Sintering imagwira ntchito yofunika kwambiri pamakampani opanga zinthu, ndikupangitsa kuti pakhale zinthu zovuta komanso zolimba. Kumvetsetsa zoyambira za sintering ndikofunikira kwa mainjiniya, ofufuza, komanso okonda chimodzimodzi. Nkhaniyi ikufuna kuzama pamalingaliro a sintering, kuwunika momwe imagwirira ntchito, kukambirana momwe imagwiritsidwira ntchito, ndikuwunikira zabwino ndi malire ake.

Kodi Sintering ndi chiyani?

Sintering ndi njira yomwe imaphatikizapo kuphatikizira zinthu zaufa kukhala zolimba popaka kutentha. Mosiyana ndi njira zachikhalidwe zosungunuka, sintering sifika posungunuka. M'malo mwake, imagwiritsa ntchito kufalikira kwa maatomu kudutsa tinthu ting'onoting'ono, zomwe zimatsogolera ku mgwirizano ndi kusamvana. Njirayi imapangitsa kuti ikhale yolimba yokhala ndi makina opangidwa bwino.

Sintering imakhalanso ndi malingaliro otakata komanso opapatiza. Kuti mumve zambiri, sintering ndi njira yomwe ufa wotayirira umaphatikizidwa kukhala midadada ndi mphamvu yomangirira yolimba pa kutentha kwina. Koma sintering m'munda wa chitsulo kupanga ndi njira amaphatikiza chitsulo ore ufa ndi zipangizo zina munali chitsulo mu zabwino zitsulo ntchito yokumba chipika ndi maphatikizidwe, kupanga ake ndi sinter. Amaphatikizanso njira zosiyanasiyana zama physicochemicals Ngakhale onsewa amagwiritsa ntchito mawu akuti sintering.

The Sintering Process

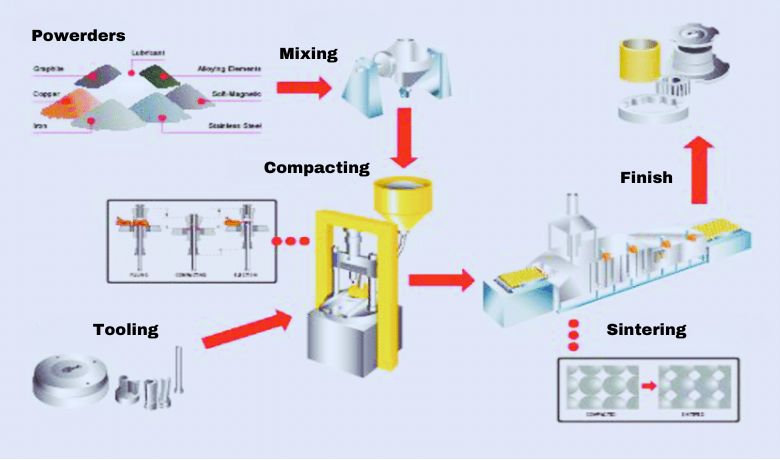

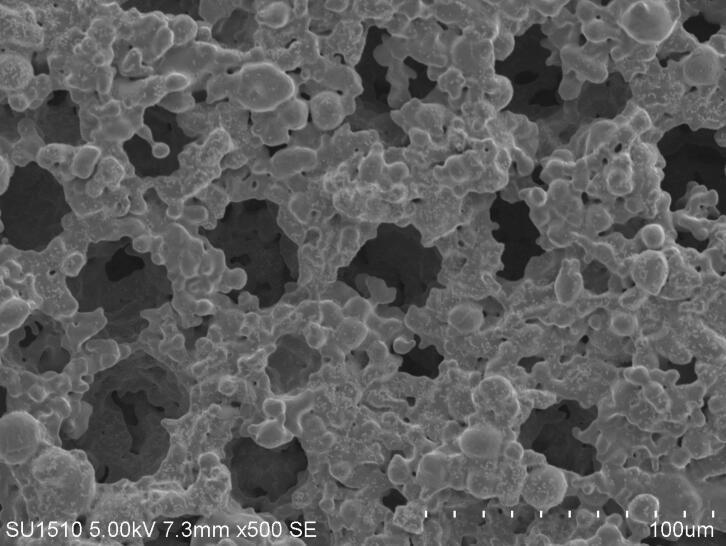

Sintering process imakhala ndi magawo angapo. Poyambirira, zopangira zimapangidwira mawonekedwe enieni, nthawi zambiri amakhala ngati ufa. Ufa umenewu umapangidwa pogwiritsa ntchito kukakamiza kuti zitsimikizire kufanana ndi kuthetsa voids. Kenako, zinthu zophatikizidwazo zimayendetsedwa ndi kutentha koyendetsedwa mu ng'anjo ya sintering. Kutentha kumayendetsedwa mosamala kuti tinthu tating'onoting'ono tigwirizane popanda kusungunuka kwathunthu. Pa kutentha, tinthu tating'onoting'ono timafalikira, zomwe zimapangitsa kuti khosi likhale lopangidwa ndi kusungunuka. Gawo lomaliza limaphatikizapo kuziziritsa kwa sintered mankhwala, kulola kuti likhale lolimba komanso logwirizana.

Ufa womwe tinkanena kuti ndi ufa wachitsulo kapena compact ufa. Ndi njira yaluso yopezera zinthu kapena mankhwala mu mphamvu zomwe zimafunikira ndi zomwe zimafunikira chifukwa cha mgwirizano wakuthupi ndi mankhwala pakati pa tinthu tating'onoting'ono pa kutentha pansi pa malo osungunuka a gawo lalikulu. HENGKO ili ndi zinthu zingapo zopangira ufa zamitundu yosiyanasiyana komanso kukula kwake kuphatikizadisk fyuluta, kapu fyuluta,fyuluta ya kandulo,pepala fyulutandi zina zotero. Sintering zitsulo zosapanga dzimbiri zili ndi mwayi wokhala ndi mphamvu zambiri, Kuthekera kwabwino, kusefera kolondola komanso kukana dzimbiri, koyenera kumadera ambiri. Ntchito zosinthidwa mwamakonda zidzaperekedwanso monga momwe mwafunira.

Njira iliyonse yopangira sintering ndi yolumikizana, ndipo kuyang'ana kwambiri ndi gawo lofunikira kwambiri pakuwotcha, ndiye kuyikako kumatanthauza chiyani?Concentrate ndi sitepe yomwe imachitapo kanthu kuti mafuta aziphika ndi mafuta azitha, kupangitsa kuti ikhale yolemetsa ya ng'anjo yomwe imakwaniritsa Zofunikira pakulimbitsa ng'anjo yoyaka moto isanakwane zida zamafuta ndi mafuta kulowa mung'anjo yophulika. Zizindikiro zapamwamba zaumisiri ndi zachuma komanso zopindulitsa zachuma zitha kupezeka pambuyo poti concentrateis ikugwiritsidwa ntchito kuphulika kwa ng'anjo yamoto. Zomwe zimatchedwa "gwiritsani ntchito bwino chilichonse" ndikugwiritsa ntchito bwino chuma. Ndi mtundu wa kuzindikira kupulumutsa ndi kuteteza chilengedwe.

Zomwe Zimakhudza Sintering

Zinthu zingapo zimakhudza momwe sintering imagwirira ntchito, kuphatikiza kutentha, kutentha, kuthamanga, kukula kwa tinthu, ndi kapangidwe kake. Kutentha kumagwira ntchito yofunika kwambiri pakuzindikira sintering kinetics ndi zotsatira zake. Kutentha kwa kutentha kumakhudza kachulukidwe, chifukwa kutentha kofulumira kungayambitse kugwirizanitsa tinthu tating'ono. Kupanikizika umagwiritsidwa ntchito panthawi yophatikizika kuti ipititse patsogolo tinthu tating'onoting'ono ndikuchotsa porosity. Kukula kwa tinthu tating'onoting'ono komanso kapangidwe kake kumakhudza momwe sintering imapangidwira, yokhala ndi tinthu ting'onoting'ono komanso nyimbo zofananira zomwe zimalimbikitsa kachulukidwe bwino.

Kuchokera ku lingaliro lenileni la mawu oti sintering, mawu oti kuyaka ndi kugwiritsa ntchito moto, payenera kukhala lawi lotsatizana ndi kutentha kwakukulu. Ndipo ndondomeko ya sintering iyenera kuchitika kutentha kwambiri. Kutentha kwakukulu kumapangidwa ndi kuyaka kwa mafuta. Kutentha osiyanasiyana, ndi moto liwiro, m'lifupi mwa woyaka gulu, mlengalenga mu zinthu sintered, etc zidzakhudza patsogolo ndondomeko sintering ndi khalidwe la zomaliza sintered mankhwala. Ndipo zinthu zimenezo zimagwirizana ndi thupi ndi mankhwala amafuta ndi mlingo. Choncho, Physical ndi mankhwala katundu wa mafuta ndi chinthu chofunika kwambiri chimene chimakhudza sintering ndondomeko.

Fanizo la chinthu sichingakhalepo popanda maziko omwe amakhala. Mafuta ndi zopangira ndizofanana ndi khungu ndipo nkhuni zomwe zili ndi ubale ndizofunikira kwambiri. Popanda ngakhale, The sintering ndondomeko sangathe kuchitika. Koma mafuta a Sintered makamaka amatanthauza mafuta olimba omwe amayaka muzinthu zosanjikiza. Ambiri ntchito ndi pulverized coke ufa ndi anthracite, etc. Sintered zopangira, makamaka ndi chitsulo, ndi manganese ore, zosungunulira, mafuta ndi zinyalala mafakitale.

Mitundu Yosiyanasiyana ya Sintering

Sintering imaphatikizapo njira zosiyanasiyana zomwe zimayikidwa potengera momwe zimagwirira ntchito komanso momwe zimagwirira ntchito. Kumvetsetsa mitundu yosiyanasiyana ya sintering ndikofunikira pakusankha njira yoyenera yogwiritsira ntchito. Nayi mitundu yodziwika bwino ya sintering:

1 Solid-State Sintering

Solid-state sintering, yomwe imadziwikanso kuti diffusion bonding, ndi njira yomwe imagwiritsidwa ntchito kwambiri sintering. Pochita izi, zida za ufa zimayikidwa pa kutentha kwakukulu pansi pa malo osungunuka. Pamene kutentha kumawonjezeka, kufalikira kwa atomiki kumachitika pakati pa tinthu tating'ono tating'ono, kumathandizira kupanga makosi ndi kugwirizana. Kuchotsa voids ndi rearrangement wa particles kumabweretsa kachulukidwe ndi mapangidwe olimba misa.

Solid-state sintering imagwiritsidwa ntchito popanga zoumba, monga porcelain ndi alumina, komanso kuyatsa zitsulo. Zimayamikiridwa pamene kusunga mankhwala ndi chiyero cha zinthu ndizofunika. Mwa kuwongolera mosamala magawo a sintering, monga kutentha, nthawi, ndi kupanikizika, zinthu zomwe mukufuna zitha kukwaniritsidwa.

2 Liquid-Phase Sintering

Liquid-phase sintering imaphatikizapo kuwonjezera gawo lamadzimadzi kuti lithandizire kukonzanso tinthu tating'onoting'ono ndikumangirira panthawi ya sintering. Gawo lamadzimadzi, lomwe nthawi zambiri limasungunuka kwambiri, limakhala ngati chomangira kapena kutulutsa, kuchepetsa kutentha kwa sintering komwe kumafunikira kuti kachulukidwe. Njirayi ndi yothandiza makamaka pamene sintering zipangizo zokhala ndi malo osungunuka kwambiri kapena pamene kulimbikitsa kuchuluka kwa kachulukidwe kumafunidwa.

Pa madzi gawo sintering, ndi madzi gawo kufalikira pakati pa particles, kulimbikitsa tinthu rearrangement ndi utithandize khosi mapangidwe ndi kachulukidwe. Kukhalapo kwa gawo lamadzimadzi kumathandizanso kuchotsedwa kwa zonyansa komanso kumathandizira kuti sintering ya zinthu ndi nyimbo zovuta.

Liquid-phase sintering imagwiritsidwa ntchito popanga simenti ya carbides, pomwe tinthu tating'ono ta tungsten carbide timamangirira pogwiritsa ntchito chomangira chopangidwa ndi cobalt. Amagwiritsidwanso ntchito poyatsa zitsulo zina zadothi ndi zitsulo, monga zitsulo zosapanga dzimbiri.

3 Kuyambitsa Sintering

Activated sintering, yomwe imadziwikanso kuti sintering-assisted sintering kapena spark plasma sintering, ndi njira yopangira sintering yomwe imagwiritsa ntchito magwero amphamvu akunja kulimbikitsa kachulukidwe. Zimaphatikizapo kugwiritsa ntchito gawo lamagetsi, magetsi, kapena ma radiation a electromagnetic kuti apititse patsogolo njira yoyatsira.

Gwero lamphamvu lakunja limathandizira kufalikira kwa atomiki, zomwe zimapangitsa kuti khosi lipangike mwachangu komanso kulimba. Kugwiritsa ntchito mphamvu zamagetsi kumapanga kutentha komweko, kuchepetsa nthawi ya sintering ndikupangitsa kuti zinthu zikhale zotentha kwambiri. Njirayi imapereka zabwino monga kukulitsa kachulukidwe, kuchepetsa kukula kwambewu, ndikuwongolera kuwongolera kwa microstructure ndi katundu.

Activated sintering amapeza ntchito m'magawo osiyanasiyana, kuphatikiza kupanga zida zapamwamba, zida zogwirira ntchito, ndi zophatikiza. Ndizopindulitsa makamaka pazinthu zomwe zimakhala ndi malo osungunuka kwambiri, zolemba zovuta, kapena zochepa zosakanikirana.

4 Mitundu ina ya Sintering

Kupatula mitundu yomwe tafotokozayi, palinso njira zingapo zapadera zopangira sintering zomwe zimapangidwira ntchito zinazake. Izi zikuphatikizapo microwave sintering, kumene mphamvu ya microwave imagwiritsidwa ntchito kutenthetsa ndi kutenthetsa zinthu, ndi sintering-assisted sintering, yomwe imaphatikiza kuthamanga ndi kutentha kuti ziwonjezere mphamvu.

Kuphatikiza apo, selective laser sintering (SLS) ndi electron beam sintering (EBS) ndi njira zopangira zowonjezera zomwe zimagwiritsa ntchito matabwa amphamvu posankha zida za ufa, wosanjikiza ndi wosanjikiza, kuti apange zinthu zovuta za mbali zitatu.

Mtundu uliwonse wa sintering umapereka mwayi wapadera ndipo umasankhidwa kutengera zinthu zakuthupi, zotsatira zomwe mukufuna, komanso kugwiritsa ntchito kwake.

Mapulogalamu a Sintering

Sintering imapeza ntchito zambiri m'mafakitale osiyanasiyana chifukwa cha kuthekera kwake kosintha zinthu zaufa kukhala zigawo zolimba zokhala ndi zinthu zowonjezera. Tiyeni tiwone mbali zina zazikulu zomwe sintering imagwiritsidwa ntchito kwambiri:

1 - Ceramics

Ceramics ndi imodzi mwamagawo oyambirira omwe sintering imagwiritsidwa ntchito kwambiri. Sintered ceramics amawonetsa mphamvu zamakina, kulimba, komanso kukhazikika kwamafuta. Sintering imagwiritsidwa ntchito popanga matailosi a ceramic, sanitaryware, zida zodulira, zida zowumitsa, ndi zotsekera magetsi. Poyang'anira mosamala magawo a sintering, zida za ceramic zitha kukwaniritsa kachulukidwe komwe mukufuna, porosity, ndi microstructure pazogwiritsa ntchito zina.

2 - Metallurgy

Muzitsulo zazitsulo, sintering imagwiritsidwa ntchito popanga zitsulo zosiyanasiyana. Izi zimaphatikizapo magiya, ma bearings, bushings, zida zamagalimoto, ndi zida zamapangidwe. Ufa wachitsulo, monga chitsulo, aluminiyamu, ndi chitsulo chosapanga dzimbiri, amaunjikana ndi kutenthedwa kuti apange mbali zolimba zokhala ndi makina abwino kwambiri. Zigawo zazitsulo zokhala ndi sintered nthawi zambiri zimawonetsa mphamvu zapamwamba, kukana kuvala, komanso kulondola kwenikweni poyerekeza ndi zida zachikhalidwe.

3 - Zophatikiza

Sintering imagwira ntchito yofunika kwambiri popanga zida zophatikizika, pomwe zida ziwiri kapena zingapo zophatikizika zimaphatikizidwa kuti zipange zida zokhala ndi zida zowonjezera. Popanga zitsulo zopangira zitsulo (MMCs) ndi ceramic matrix composites (CMCs), sintering imagwiritsidwa ntchito kumangiriza zida zolimbikitsira, monga ulusi kapena tinthu tating'onoting'ono, ndi matrix. Izi zimawonjezera mphamvu, kuuma, ndi kulimba kwa zinthu zomwe zimapangidwira.

4 - Ufa Metallurgy

Powder metallurgy, nthambi yapadera yazitsulo, imadalira kwambiri sintering. Zimaphatikizapo kupanga zigawo zachitsulo kuchokera ku ufa wazitsulo. Kupyolera mu njira monga compaction ndi sintering, ziwalo zovuta ndi mawonekedwe ovuta akhoza kupangidwa. Zitsulo za ufa zimagwiritsidwa ntchito kwambiri pamakampani opanga magalimoto popanga magiya, ma camshafts, mipando ya valve, komanso kupanga zida zodulira ndi zosefera za sintered.

5 - Kusindikiza kwa 3D / Kupanga Zowonjezera

Sintering imatenga gawo lofunikira munjira zopangira zowonjezera monga selective laser sintering (SLS) ndi electron beam sintering (EBS). Munjira izi, zida zaufa zimasankhidwa mosankhidwa kukhala wosanjikiza ndi wosanjikiza, kutengera mapangidwe a digito, kuti apange zinthu zovuta zamitundu itatu. Sintering imalola kuphatikizika ndi kugwirizana kwa zinthu za ufa, zomwe zimapangitsa kuti zikhale zowundana komanso zimagwira ntchito. Ukadaulo uwu umagwiritsidwa ntchito m'mafakitale osiyanasiyana, kuphatikiza zakuthambo, zaumoyo, ndi ma prototyping.

6 Electronics ndi Electrical Engineering

Sintering imagwiritsidwa ntchito popanga zida zamagetsi ndi zamagetsi. Popanga zida zamagetsi zamagetsi, monga ma capacitors, varistors, ndi thermistors, sintering imagwiritsidwa ntchito kumangiriza tinthu tating'onoting'ono ta ceramic, kupanga zowuma komanso zopangira magetsi. Sintering imagwiritsidwanso ntchito popanga ma contacts amagetsi, ma semiconductor packaging, ndi zigawo za board board.

Izi ndi zitsanzo zochepa chabe za ntchito zosiyanasiyana za sintering. Njirayi ikufufuzidwa mosalekeza ndikuyengedwa kuti ikwaniritse zosowa zamakampani osiyanasiyana, zomwe zimathandizira kupanga zida zogwirira ntchito kwambiri komanso zigawo.

Ubwino wa Sintering

Sintering imapereka maubwino angapo omwe amapangitsa kuti ikhale njira yabwino yopangira m'mafakitale osiyanasiyana. Tiyeni tiwone zina mwazabwino zazikulu:

1 Mawonekedwe Ovuta Ndi Mapangidwe Ovuta

Ubwino umodzi wofunikira wa sintering ndi kuthekera kwake kupanga zida zokhala ndi mawonekedwe ovuta komanso mapangidwe ovuta. Pogwiritsa ntchito zida zaufa, sintering imalola kupanga magawo okhala ndi ma geometries ovuta kwambiri omwe angakhale ovuta kukwaniritsa pogwiritsa ntchito njira zamachikale. Kusinthasintha kumeneku pakupanga kumathandizira kupanga zida zosinthidwa zomwe zimapangidwira ntchito zinazake.

2 Katundu Wamakina Wotukuka

Sintering imakulitsa mawonekedwe azinthu zamakina, zomwe zimapangitsa kuti zigawo zomwe zili ndi magwiridwe antchito apamwamba. Pa ndondomeko sintering, ndi particles chomangira ndi densify, zikubweretsa patsogolo mphamvu, kuuma, ndi kuvala kukana kwa sintered mankhwala. Njira zowongolera zotenthetsera ndi kufalikira zomwe zimakhudzidwa ndi sintering zimathandizira kuti pakhale mawonekedwe owundana komanso ogwirizana, kukulitsa kukhulupirika kwamakina kwa gawolo.

3 Zolemba Zogwirizana

Sintering imalola kuphatikizika kwa ufa wokhala ndi nyimbo zosiyanasiyana, zomwe zimapangitsa kupanga zinthu zokhala ndi zida zogwirizana. Pophatikiza mitundu yosiyanasiyana ya ufa kapena kuphatikiza zowonjezera, ndizotheka kusintha mawonekedwe azinthu malinga ndi zofunikira zenizeni. Kusinthasintha kumeneku kumatsegula mwayi wopanga zida zapamwamba zogwira ntchito bwino, monga ma aloyi amphamvu kwambiri kapena zida zokhala ndi magetsi kapena matenthedwe.

4 Kugwiritsa Ntchito Ndalama

Sintering ndi njira yopangira zinthu zotsika mtengo poyerekeza ndi njira zachikhalidwe zosungunula ndi zoponya. Kugwiritsa ntchito zinthu zaufa kumachepetsa zinyalala zakuthupi, chifukwa ufa wochuluka ukhoza kusonkhanitsidwa ndikugwiritsidwanso ntchito. Kuonjezera apo, ndondomeko ya sintering imafuna mphamvu zochepa zogwiritsira ntchito mphamvu chifukwa zimagwira ntchito pa kutentha pansi pa malo osungunuka a zinthuzo. Kuthekera kopanga zida zokhala ndi mawonekedwe apafupi ndi ukonde kumachepetsanso kufunika kwa machining omwe amatsatira, zomwe zimapangitsa kuti pakhale ndalama zochepetsera kugwiritsa ntchito zinthu, kugwiritsa ntchito mphamvu, komanso kukonza pambuyo pake.

5 Kusinthasintha Posankha Zinthu

Sintering imapereka kusinthasintha pakusankha zinthu, kukhala ndi zida zambiri zamagwiritsidwe osiyanasiyana. Ndi yoyenera pazitsulo za ceramic, zitsulo, ndi ma composite. Mitundu yosiyanasiyana ya zida, kuphatikiza ma oxides, ma carbides, nitrides, ndi ma aloyi, amatha kukonzedwa kudzera mu sintering. Kuphatikizika kwazinthu zazikuluzikulu kumalola kupanga magawo osiyanasiyana okhala ndi zinthu zina zakuthupi, kupanga sintering kukhala chisankho chokongola kwa mafakitale angapo.

Ubwino wa Sintering pakuumba movutikira, kuwongolera kwamakina, zida zopangidwira, zotsika mtengo, komanso kusinthika kwazinthu kumapangitsa kuti ikhale yofunikira kupanga m'magawo osiyanasiyana. Pogwiritsa ntchito zopindulitsa izi, mafakitale amatha kupanga bwino, kupititsa patsogolo magwiridwe antchito, ndikuchepetsa ndalama pakupangira kwawo.

Pali zosintha zambiri kuphatikizapo kusintha kwa thupi ndi mankhwala. Thupi ndi mankhwala zimachitikira mu ufa sintering kuphatikizapo evaporation kapena evaporation madzi kapena organic kanthu, kuchotsa adsorbed mpweya, kuchepetsa nkhawa, kuchepetsa oxides pamwamba pa ufa particles, kusamuka kwa zinthu, recrystallization, kukula kwambewu, etc. Ndikofunikira kwambiri kuphunzira ndi kumvetsetsa chidziwitso cha sintering ngati wopanga. Ndipo monga ogula, kuphunzira zidziwitso zoyambirirazi kungatithandize kukhala ndi lingaliro labwino posankha zinthu za sintering.

Sintering ndi njira yachikhalidwe komanso yovuta. Nthawi zikupita patsogolo, Ndipo ukadaulo wopanga ndi zida zopangira zimasinthidwanso nthawi zonse. Sungani zidziwitso zoyambira ndikuphunzira zatsopano ndizofunikira kwa ogwira nawo ntchito. Kwa zaka 18 zapitazo.HENGKOnthawi zonse amalimbikira kudzikonza yekha, kupatsa makasitomala zinthu zabwino ndi ntchito zoganizira, kuthandiza makasitomala ndi chitukuko wamba. Tikuyembekeza kukhala bwenzi lanu lodalirika la nthawi yayitali.

FAQ (Mafunso Ofunsidwa Kawirikawiri)

Ndi zinthu ziti zomwe zingasinthidwe?

Zida zambiri zimatha kutenthedwa, kuphatikizapo ceramic, zitsulo, ndi kompositi. Zitsanzo zimaphatikizapo ufa wa ceramic monga alumina ndi zirconia, ufa wachitsulo ngati chitsulo ndizosefera zitsulo zosapanga dzimbiri za sintered, ndi ufa wophatikizika wokhala ndi zida zolimbikitsira monga ulusi kapena tinthu ting'onoting'ono.

Kodi ubwino wa sintering ndi chiyani poyerekeza ndi njira zina zopangira?

Sintering imapereka maubwino angapo kuposa njira zachikhalidwe zopangira. Imalola kupanga zigawo zokhala ndi mawonekedwe ovuta komanso mapangidwe odabwitsa, imapereka zida zamakina zowongoka bwino, zimathandizira kusinthika kwazinthu zakuthupi, zimakhala zotsika mtengo chifukwa cha kuchepa kwa zinyalala zakuthupi, komanso zimakhala ndi zida zosiyanasiyana zogwirira ntchito zosiyanasiyana.

Kodi ntchito zazikulu za sintering ndi ziti?

Sintering imapeza ntchito m'mafakitale monga zoumba, zitsulo, zitsulo za ufa, zamagetsi, ndi zopangira zowonjezera. Amagwiritsidwa ntchito popanga matailosi a ceramic, zida zamagalimoto, zida zachitsulo, zida zodulira, zida zamagetsi zamagetsi, ndi zinthu zosindikizidwa za 3D, pakati pa ena.

Kodi pali zolepheretsa kapena zovuta zilizonse ndi sintering?

Sintering ili ndi malire ndi zovuta zina. Kupeza kachulukidwe kofanana muzinthu zonse kungakhale kovuta, chifukwa kutentha kosafanana kapena kugawa kwa tinthu kungayambitse zolakwika. Kuwongolera kukula kwa mbewu ndi kupewa kuchulukira kwambiri panthawi ya sintering ndizofunikiranso. Kuonjezera apo, sizinthu zonse zomwe zili zoyenera kuti zisungunuke chifukwa cha malo osungunuka kwambiri kapena reactivity ndi mlengalenga wozungulira.

Kodi njira zosiyanasiyana zochitira sintering ndi ziti?

Pali njira zosiyanasiyana zochitira sintering, kuphatikizapo solid-state sintering, liquid-phase sintering, activated sintering, microwave sintering, pressure-assisted sintering, komanso njira zapadera monga selective laser sintering (SLS) ndi electron beam sintering (EBS). Njira iliyonse ili ndi njira zake zapadera ndipo imasankhidwa malinga ndi zofunikira zakuthupi ndi ntchito.

Kodi sintering imakweza bwanji zinthu zakuthupi?

Sintering imapangitsa kuti zinthu ziziyenda bwino polimbikitsa kulumikizana kwa tinthu ndi kachulukidwe. Panthawi ya sintering, tinthu tating'onoting'ono timatulutsa timadzi timene timatulutsa timadzi timene timatulutsa timadzi timene timapanga khosi komanso kachulukidwe. Izi zimabweretsa kuwonjezereka kwamakina monga mphamvu, kuuma, ndi kukana kuvala. Kuphatikiza apo, sintering imatha kupititsa patsogolo mphamvu zamagetsi, kutentha, ndi mankhwala kutengera zinthu ndi kapangidwe kake.

Kodi ma sintered atha kupangidwa kapena kukonzedwanso?

Inde, mbali zowombedwa zimatha kukonzedwanso kapena kupanga makina, ngati pakufunika. Ngakhale kuti sintering imatha kukwaniritsa zigawo zamtundu wa ukonde, pakhoza kukhala nthawi zina pomwe makina owonjezera kapena kukonzanso pambuyo pake ndikofunikira kuti akwaniritse zomwe mukufuna. Njira zopangira makina monga mphero, kubowola, kapena kugaya zitha kugwiritsidwa ntchito kuti mukwaniritse zomaliza kapena kumaliza.

Kodi zolingalira zachilengedwe za sintering ndi ziti?

Sintering nthawi zambiri imatengedwa ngati njira yopangira zinthu zachilengedwe. Imawononga mphamvu zochepa poyerekeza ndi njira zosungunulira ndi zoponyera, ndipo imachepetsa zinyalala zakuthupi polola kugwiritsanso ntchito ufa wowonjezera. Komabe, ndikofunikira kuganizira momwe chilengedwe chimakhudzira zinthu zomwe zimagwiritsidwa ntchito, komanso kasamalidwe koyenera ndi kutaya kwazinthu zilizonse kapena zinyalala zomwe zimapangidwa panthawiyi.

Kodi sintering imathandizira bwanji kupanga zida zapamwamba?

Sintering imagwira ntchito yofunika kwambiri pakupanga zida zapamwamba. Mwa kusankha mosamala ndi kulamulira zikuchokera, tinthu kukula, ndi sintering magawo, n'zotheka kuti agwirizane zimatha chifukwa zakuthupi. Izi zimapangitsa kuti pakhale zipangizo zamakono zokhala ndi makhalidwe enaake, monga ma alloys apamwamba kwambiri, zoumba zogwirira ntchito, kapena zipangizo zophatikizika zomwe zimakhala ndi katundu wapadera.

Ngati muli ndi mafunso ena kapena mukufuna kulumikizana nawoHENGKO,

chonde omasuka kulankhula nafe kudzera imelo paka@hengko.com.

Tingakhale okondwa kukuthandizani ndikukupatsani zina zowonjezera zomwe mungafune.

Nthawi yotumiza: Aug-14-2020