-

yotakata pakamwa mtsuko womanga mtsuko ndi zosapanga dzimbiri sintered fyuluta chimbale kutentha kwambiri ...

Zosintha zazing'ono, zopindulitsa zazikulu! Timasunga dongo la bentonite mkati mwa mtsuko ndikuwotcha mu uvuni wa vacuum kuti tichotse chinyezi. Ngakhale ndi chivindikiro pa dongo amatuluka ...

Onani Tsatanetsatane -

Monocrystalline silicon kuthamanga transmitter sintered zitsulo porous fyuluta chimbale

Pogwiritsa ntchito crystal silicon piezoresistive technology pressure sensor, process industry liquid level muyeso ntchito sintered fyuluta chimbale:...

Onani Tsatanetsatane -

Sefa ya Sintered Porous Metal Leaf Disc Yamakampani a Polima Sungunulani

Zosefera za Leaf Disc ndi Solid Plate zopangira zosefera za polima zotentha kwambiri. Leaf chimbale ndi zosefera mbale olimba anapangidwa kuti h yovuta ...

Onani Tsatanetsatane -

Sintered porous metal fyuluta chimbale 20 micron kwa Gasi kuyeretsa ndi kusanthula

Pezani Kupatukana Kosafanana ndi Gasi/Zolimba Ndi Ma Diski a Sintered Stainless Steel Flutter a HENGKO! Makina athu osefera, okhala ndi sintered zosapanga dzimbiri ...

Onani Tsatanetsatane -

HENGKO porous metal disc test test fyuluta yoyesera benchi ya Laboratory

Zabwino kwa: - Kuyesa kwa benchi ya Laboratory -Kafukufuku wotheka -Kang'ono kakang'ono, kachitidwe ka batch-mtundu wa mapangidwe a HENGKO ndikupanga fyuluta pamwamba pa benchi, po...

Onani Tsatanetsatane -

Sefa ya Porous Metal Sintered Stainless Steel Disc Sefa ya Fiberf Yarn Production / P...

Zosefera za Porous Metal za HENGKO zosefera zachitsulo za porous za HENGKO zimapereka moyo wochulukira komanso magwiridwe antchito pakusefera kwa polima. Zosefera ndi sintered,...

Onani Tsatanetsatane -

47mm Porous Disc Fyuluta 316L SS Sintered Metal Fyuluta ya Laboratory Bench Scale Testing

Fyuluta yapa benchi ya HENGKO (47mm disc test fyuluta), fyuluta yathu ya 47mm disc, ndi njira yosavuta, yotsika mtengo yopangira kupatukana kwamadzi-olimba ndi gasi ndi ...

Onani Tsatanetsatane -

4-20mA Infuraredi CH4 CO2 mpweya sensa ( carbon dioxide sensa) chowunikira zotayidwa aloyi aloyi ...

Nyumba zazitsulo zosapanga dzimbiri zotetezedwa ndi tamperproof. Kuti mugwiritse ntchito ndi mabokosi ovomerezeka padera, ophatikizira mulingo wamakampani kapena zotchingira mpweya wa OEM. ...

Onani Tsatanetsatane -

Kutsekereza moto ndi odana ndi kuphulika sintered nyumba ndi sintered fyuluta chimbale kwa ga ...

Zomangamanga za sensa zosaphulika zimapangidwa ndi zitsulo zosapanga dzimbiri 316 kuti zitetezeke kwambiri pakuwononga dzimbiri. Chomangira chamoto chokhala ndi sinter-bonded chimapereka kufalikira kwa gasi ...

Onani Tsatanetsatane -

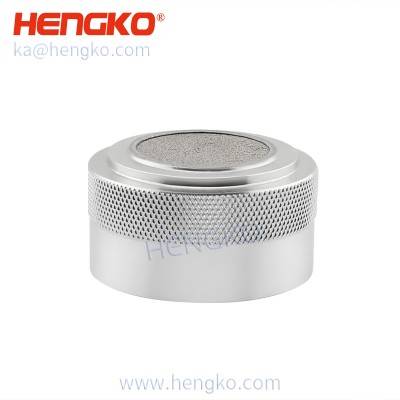

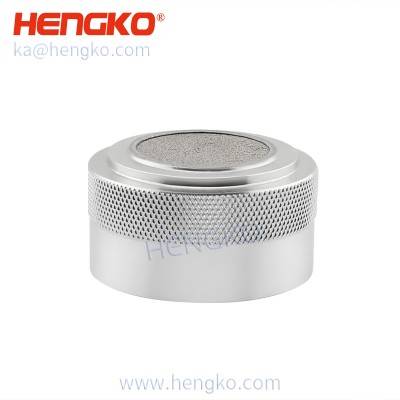

Zovala zodzitchinjiriza za Sensor ya Gasi yokhala ndi sintered powder metal stainless steel filter disc

Magulu a sensor proof proof sensor amapangidwa ndi chitsulo chosapanga dzimbiri cha 316 kuti chitetezeke kwambiri pakuwononga dzimbiri. Sinter yomangika lawi lamoto imapereka kufalikira kwa gasi ...

Onani Tsatanetsatane -

Zitsulo zosapanga dzimbiri zomangira moto zowonera nyumba zotetezedwa ndi mpweya wa monoxide ...

Zomangamanga za sensa zosaphulika zimapangidwa ndi zitsulo zosapanga dzimbiri 316 kuti zitetezeke kwambiri pakuwononga dzimbiri. Chomangira chamoto chokhala ndi sinter-bonded chimapereka kufalikira kwa gasi ...

Onani Tsatanetsatane -

sintered zosapanga dzimbiri 316L zitsulo porous mpweya kachipangizo Alamu mpanda madzi + sint ...

Zomangamanga za sensa zosaphulika zimapangidwa ndi zitsulo zosapanga dzimbiri 316 kuti zitetezeke kwambiri pakuwononga dzimbiri. Chomangira chamoto chokhala ndi sinter-bonded chimapereka kufalikira kwa gasi ...

Onani Tsatanetsatane -

madzi porous zosapanga dzimbiri zitsulo kuphulika-umboni mpweya kachipangizo kafukufuku zoteteza chimakwirira ndi ...

Nyumba ya sensor yophulika ya HENGKO imapangidwa ndi chitsulo chosapanga dzimbiri cha 316L ndi aluminiyamu kuti itetezere dzimbiri. Womanga moto wokhala ndi sinter-bonded amapereka ...

Onani Tsatanetsatane -

Micron Sintered Porous sintered zosapanga dzimbiri 316L zitsulo porous gas sensor alarm expl...

Nyumba ya sensor yophulika ya HENGKO imapangidwa ndi chitsulo chosapanga dzimbiri cha 316L ndi aluminiyamu kuti itetezere dzimbiri. Womanga moto wokhala ndi sinter-bonded amapereka ...

Onani Tsatanetsatane -

Analogi carbon dioxide co2 fixed mpweya chowunikira sintered zosapanga dzimbiri kafukufuku ndi IP66 maola ...

Nyumba ya sensor yophulika ya HENGKO imapangidwa ndi chitsulo chosapanga dzimbiri cha 316L ndi aluminiyamu kuti itetezere dzimbiri. Womanga moto wokhala ndi sinter-bonded amapereka ...

Onani Tsatanetsatane -

Chigawo chojambulira gasi-Chitsimikizo cha Kuphulika kwa Stainless Steel Probe Filter Caps Protect...

Nyumba ya sensor yophulika ya HENGKO imapangidwa ndi chitsulo chosapanga dzimbiri cha 316L ndi aluminiyamu kuti itetezere dzimbiri. Womanga moto wokhala ndi sinter-bonded amapereka ...

Onani Tsatanetsatane -

Sintered Stainless Stainless Steel 316L/316 Sefa Chimbale Chogwiritsidwa Ntchito Pachitetezo Chodzitchinjiriza cha Gasi ...

Nyumba ya sensor yophulika ya HENGKO imapangidwa ndi chitsulo chosapanga dzimbiri cha 316L ndi aluminiyamu kuti itetezere dzimbiri. Womanga moto wokhala ndi sinter-bonded amapereka ...

Onani Tsatanetsatane -

Zosefera zachitsulo zosapanga dzimbiri zosapanga dzimbiri zotchingira moto komanso kukana moto

Zida zachitsulo zokhala ndi sintered ndizosankha zodziwika bwino chifukwa zida zopangidwa mwaluso kwambirizi zimakhala ndi yunifolomu, yolumikizidwa yomwe imatha kupangidwa ...

Onani Tsatanetsatane -

Sintered Stainless Stainless Steel Sanitary Tri Clamp Selter Disc yokhala ndi Viton O-Ring frit Gasket f...

Ku HENGKO® timayesetsa kuthandiza makasitomala athu kupanga ntchito zapamwamba, zotetezeka, komanso zolondola pakukonza hemp. Zida zabwino kwambiri za CBD zomwe timapeza ...

Onani Tsatanetsatane -

Mu Line Porous Metal Sintered Sefa Zosefera Zosefera Zosefera -HENGKO

HENGKO imapanga makina ochapira a Venus, Kitty, Class, ndi Musa Moka. Phukusili limaphatikizapo chochapira ndi mbale ya fyuluta ya khofi. Gasket diameterChonde...

Onani Tsatanetsatane

Mitundu ya Zosefera za Sintered Disc

Zosefera za Sintered disc zimagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana chifukwa cha kulimba kwawo, kusefera kwakukulu,

ndi kuthekera kogwira ntchito m'malo ovuta kwambiri. Pansipa pali mitundu yodziwika bwino ya zosefera za sintered disc:

1. Zosefera Zosapanga dzimbiri za Sintered Disc

*Zakuthupi: Amapangidwa kuchokera ku 316L chitsulo chosapanga dzimbiri.

*Magwiritsidwe: Amagwiritsidwa ntchito m'mafakitale opangira mankhwala, zakudya ndi zakumwa, komanso kusefera gasi chifukwa cha kukana kwawo.

ku dzimbiri ndi kutentha kwambiri.

*Zida: Mphamvu zamakina zabwino kwambiri, kukana kwa dzimbiri, ndipo zitha kugwiritsidwa ntchito pakusefera kwamadzi ndi gasi.

2. Zosefera za Bronze Sintered Disc

*Zakuthupi: Wopangidwa ndi tinthu tating'ono ta mkuwa.

*Mapulogalamu: Nthawi zambiri amagwiritsidwa ntchito pamakina a pneumatic, makina opaka mafuta, ndi ma hydraulic system.

*Zowoneka: Kukana bwino kuvala ndipo kumatha kugwira ntchito m'malo omwe mafuta ndi zothira zina zilipo.

3. Zosefera za Nickel Sintered Disc

*Zakuthupi: Zopangidwa kuchokera ku sintered nickel particles.

*Mapulogalamu: Oyenera kumadera otentha kwambiri komanso amagwiritsidwa ntchito m'mafakitale azamlengalenga ndi petrochemical.

* Zowoneka: Kutentha kwabwino kwambiri komanso kukana makutidwe ndi okosijeni.

4. Zosefera za Titanium Sintered Disc

*Zinthu: Zopangidwa kuchokera ku titaniyamu ya sintered.

*Mapulogalamu: Ndiabwino pazamankhwala, biotechnology, ndi ntchito zamankhwala chifukwa cha kuyanjana kwawo

ndi kukana dzimbiri.

* Zowoneka: Chiyerekezo champhamvu-kulemera kwamphamvu, kukana kwa dzimbiri kwabwino kwambiri, komanso koyenera malo owononga kwambiri.

5. Zosefera za Hastelloy Sintered Disc

*Zida: Zopangidwa kuchokera ku Hastelloy alloys.

*Mapulogalamu: Amagwiritsidwa ntchito pokonza mankhwala komanso malo ovuta komwe kukana asidi ndi

zinthu zina zowononga ndizofunikira.

*Zowoneka: Kukana kwapadera pobowola, kusweka kwa dzimbiri, komanso kutentha kwambiri kwa okosijeni.

6. Zosefera za Inconel Sintered Disc

*Zakuthupi: Wopangidwa ndi ma Inconel alloys.

*Mapulogalamu: Amagwiritsidwa ntchito kwambiri m'mafakitale opangira zamlengalenga, zam'madzi, komanso zamagetsi.

* Zowoneka: Kukana kwabwino kwambiri pakutentha kwambiri komanso ma oxidation, kuwapangitsa kukhala oyenera malo owopsa.

7. Zosefera za Monel Sintered Disc

*Zida: Zopangidwa kuchokera ku ma alloys a Monel, makamaka faifi tambala ndi mkuwa.

*Magwiritsidwe: Amagwiritsidwa ntchito m'mafakitale apanyanja, makemikolo, ndi mafuta.

*Zida: Mphamvu yayikulu komanso kukana kwamadzi am'nyanja, zomwe zimawapangitsa kukhala abwino kugwiritsa ntchito panyanja.

8. Zosefera za Porous Ceramic Sintered Disc

*Zida: Zopangidwa kuchokera ku sintered ceramic zida.

*Magwiritsidwe: Amagwiritsidwa ntchito posefera mankhwala aukali, mpweya wotentha, komanso poyeretsa madzi.

*Zida: Kukhazikika kwamankhwala kwabwino, kukana kutentha kwambiri, ndipo kumatha kugwira ntchito m'malo okhala acidic kwambiri kapena oyambira.

Mtundu uliwonse wa sintered chimbale fyuluta ali ndi katundu wake wapadera kuti kukhala oyenera ntchito yeniyeni,

kutengera zinthu monga kutentha, ngakhale mankhwala, ndi mphamvu makina.

Mbali Zazikulu za Porous Sintered Stainless Steel Disc

1. Mphamvu Zapamwamba Zamakina

- Mbali: Ma disks awa amadziwika chifukwa cha mphamvu zawo zamakina, zomwe zimawalola kupirira kupsinjika kwakukulu komanso kupsinjika kwamakina.

- Phindu: Ndioyenera kugwiritsa ntchito zomwe zimagwira ntchito movutirapo, monga makina osefera othamanga kwambiri.

2. Kukanika kwa dzimbiri

- Mbali: Opangidwa kuchokera ku chitsulo chosapanga dzimbiri, nthawi zambiri 316L, ma disc awa amawonetsa kukana kwambiri kwa dzimbiri ndi okosijeni.

- Phindu: Ndibwino kuti mugwiritse ntchito m'malo owopsa amankhwala, kuphatikiza acidic, alkaline, ndi saline.

3. Kulimbana ndi Kutentha

- Mbali: Sintered stainless steel discs amatha kugwira ntchito zosiyanasiyana kutentha, kuchokera ku cryogenic kupita kumalo otentha kwambiri.

- Phindu: Oyenera ntchito zomwe zimafuna kukhazikika kwamafuta, monga kusefera kwa gasi munjira zotentha kwambiri.

4. Mapangidwe a Pore Ofanana

- Chiwonetsero: Njira yopangira sintering imapanga mawonekedwe ofananirako komanso olondola a pore mu diski yonse.

- Phindu: Amapereka ntchito zosefera mosasinthasintha, kuwonetsetsa kuti tinthu tating'ono ting'onoting'ono tisungidwe komanso kukwanira kwamadzimadzi.

5. Reusability

- Chiwonetsero: Ma disks awa amatha kutsukidwa ndikugwiritsidwanso ntchito kangapo popanda kutaya kukhulupirika kwawo kapena kusefera bwino.

- Phindu: Zotsika mtengo pakapita nthawi, chifukwa zimachepetsa kufunika kosintha pafupipafupi.

6. Customizable Pore Kukula

- Mbali: The pore kukula kwa zimbale akhoza makonda pa kupanga ndondomeko, kuyambira ma microns angapo kuti mazana angapo microns.

- Phindu: Imalola njira zosefera zofananira kuti zikwaniritse zofunikira za pulogalamuyo, kaya kusefa bwino kapena kowawa.

7. Kugwirizana kwa Chemical

- Chitsulo: Sintered zosapanga dzimbiri zimagwirizana ndi mankhwala osiyanasiyana, kuphatikizapo zosungunulira, ma asidi, ndi mpweya.

- Phindu: Zosiyanasiyana kuti zigwiritsidwe ntchito m'mafakitale osiyanasiyana monga kukonza mankhwala, mankhwala, zakudya ndi zakumwa.

8. High Permeability

- Mbali: Ngakhale ali mkulu kusefera dzuwa, zimbale izi kupereka mkulu permeability, kulola imayenera otaya mitengo ya zakumwa ndi mpweya.

- Phindu: Imakulitsa magwiridwe antchito, makamaka pamapulogalamu omwe amafunikira kutulutsa kwakukulu popanda kusokoneza kusefera.

9. Kukhalitsa ndi Moyo Wautali

- Chiwonetsero: Chikhalidwe cholimba cha chitsulo chosapanga dzimbiri, chophatikizidwa ndi mphamvu yoperekedwa ndi ndondomeko ya sintering, imapangitsa kuti ikhale yolimba kwambiri.

- Phindu: Moyo wautali wautumiki umachepetsa kukonzanso ndi kubweza ndalama, kuzipanga kukhala chisankho chodalirika pakugwiritsa ntchito nthawi yayitali.

10. Thermal Shock Resistance

- Mbali: Sintered zosapanga dzimbiri zimbale akhoza kupirira kusintha mwadzidzidzi kutentha popanda kusweka kapena kutaya structural umphumphu.

- Phindu: Oyenera kugwiritsa ntchito ndi kutentha kosiyanasiyana, monga mumlengalenga kapena gasi wamakampani.

11. Kusakhetsa

- Chiwonetsero: Mapangidwe olimba komanso okhazikika a sintered disc amalepheretsa kukhetsedwa kapena kutulutsidwa kwa tinthu.

- Phindu: Imawonetsetsa kuti zosefedwazo zimakhalabe zopanda kuipitsidwa, ndizofunikira kwambiri pazamankhwala ndi kukonza zakudya.

12. Zosavuta Kupanga ndi Kuphatikizira

- Mbali: Izi zimbale mosavuta anapangidwa mu akalumikidzidwa zosiyanasiyana ndi makulidwe, ndipo akhoza Integrated mu machitidwe osiyanasiyana.

- Phindu: Amapereka kusinthasintha kwa mapangidwe ndi kugwirizana ndi machitidwe kapena zida zomwe zilipo kale, kuzipangitsa kuti zigwirizane ndi ntchito zosiyanasiyana.

Izi zimapangitsa ma porous sintered stainless steel discs kukhala chisankho chodziwika bwino pantchito zamafakitale, pomwe kulimba, kudalirika, komanso kuchita bwino ndikofunikira.

Kufananiza Magwiridwe Amitundu Yosiyanasiyana ya Sintered Metal Disc

Kufananiza kwa Magwiridwe a Sintered Metal Discs

| Zakuthupi | Mphamvu zamakina | Kukaniza kwa Corrosion | Kulimbana ndi Kutentha | Kugwirizana kwa Chemical | Ntchito Zofananira |

|---|---|---|---|---|---|

| Chitsulo chosapanga dzimbiri (316L) | Wapamwamba | Wapamwamba | Kukwera (mpaka 600°C) | Zabwino kwambiri | Chemical processing, chakudya & chakumwa, gasi kusefera |

| Bronze | Wapakati | Wapakati | Zochepa (mpaka 250 ° C) | Zabwino | Pneumatic systems, lubrication systems |

| Nickel | Wapamwamba | Wapamwamba | Kwambiri kwambiri (mpaka 1000°C) | Zabwino kwambiri | Azamlengalenga, mafakitale petrochemical |

| Titaniyamu | Wapamwamba | Wapamwamba kwambiri | Kukwera (mpaka 500°C) | Zabwino kwambiri | Pharmaceutical, biotechnology, ntchito zamankhwala |

| Hastelloy | Wapamwamba | Wapamwamba kwambiri | Kukwera Kwambiri (mpaka 1093°C) | Zabwino kwambiri | Chemical processing, madera ovuta |

| Inconel | Wapamwamba kwambiri | Wapamwamba kwambiri | Kukwera Kwambiri (mpaka 1150 ° C) | Zabwino kwambiri | Azamlengalenga, m'madzi, mankhwala processing |

| Moneli | Wapamwamba | Wapamwamba | Kukwera (mpaka 450 ° C) | Zabwino | Marine, mankhwala, mafakitale a petroleum |

| Porous Ceramic | Wapakati | Wapamwamba kwambiri | Kwambiri (mpaka 1600 ° C) | Zabwino kwambiri | Kusefa mankhwala aukali, mpweya wotentha, mankhwala madzi |

| Alumina | Wapamwamba | Wapamwamba | Kwambiri (mpaka 1700 ° C) | Zabwino kwambiri | High-kutentha ntchito, mankhwala inertness chofunika |

| Silicon Carbide | Wapamwamba kwambiri | Wapamwamba | Kukwera Kwambiri (mpaka 1650 ° C) | Zabwino kwambiri | Malo owononga komanso owononga |

FAQ

Kodi ma porous sintered stainless steel discs ndi chiyani?

Poroussintered zosapanga dzimbiri zimbalendi zida zapadera zosefera zomwe zimapangidwa pothira ufa wachitsulo chosapanga dzimbiri kukhala cholimba chokhala ndi ma pores olumikizana. The sintering ndondomeko imasakaniza zitsulo particles palimodzi, kupanga olimba, porous zinthu zoyenera kusefera, kulekana, ndi kufalitsa ntchito. Ma disks awa amapereka mphamvu zamakina, kukana kwa dzimbiri, komanso kulekerera kutentha kwambiri, zomwe zimawapangitsa kukhala oyenera kugwiritsidwa ntchito m'mafakitale osiyanasiyana monga chakudya, mankhwala, ndi kukonza mankhwala.

Kodi zinthu zazikulu ndi zopindulitsa za porous sintered stainless steel discs ndi ziti?

- Kukhalitsa Kwapadera:Mphamvu zamakina apamwamba komanso kukhazikika zimatsimikizira kugwira ntchito kwanthawi yayitali.

- Superior Corrosion Resistance:Kugonjetsedwa ndi mankhwala osiyanasiyana, kuphatikizapo ma asidi, alkalis, ndi abrasives.

- Kulekerera Kwabwino Kwambiri Kutentha:Oyenera kugwira ntchito pa kutentha kuchokera -200 ° C mpaka 600 ° C.

- Sefa Yeniyeni:Amapezeka m'makalasi angapo osefera kuti akwaniritse zofunikira zenizeni.

- Dothi Lalikulu:Amajambula bwino ndikusunga zowononga.

- Kukonza Kosavuta:Zosavuta kuyeretsa ndikugwiritsanso ntchito, kuchepetsa nthawi yopuma.

- Zokonda Zokonda:Ikhoza kupangidwa kuti igwirizane ndi maonekedwe osiyanasiyana, kukula kwake, ndi zosowa zakuthupi.

- Kukhwimitsa Kwambiri:Mapangidwe amodzi kapena angapo amawonjezera mphamvu zamapangidwe.

Ndi zipangizo ziti zomwe zimagwiritsidwa ntchito popanga porous sintered stainless steel discs?

Porous sintered zosapanga dzimbiri zimbale makamaka anapangidwa kuchokera zosapanga dzimbiri zipangizo, monga 316L, 304L, 310S, 321, ndi 904L.

Ma alloys awa amasankhidwa chifukwa chokana dzimbiri, mphamvu, komanso kulimba. Zida zina monga titaniyamu, Hastelloy,

Inconel, ndi Monel zitha kugwiritsidwanso ntchito kukwaniritsa zofunikira.

Ndi magawo ati osefera omwe alipo porous sintered stainless steel discs?

Ma porous sintered stainless steel discs amapezeka mumitundu yosiyanasiyana yosefera, kuyambira 0.1 μm mpaka 100 μm, kuti agwirizane ndi zosowa zosiyanasiyana zosefera.

Gawo la kusefera limatsimikiziridwa ndi kukula kwa ma pores olumikizidwa mu chitsulo chosungunuka. Makalasi osefera bwino, monga 0.1 μm

kapena 0.3 μm, ndizoyenera kugwiritsa ntchito zomwe zimafuna chiyero chachikulu komanso kuchotsedwa kwa tinthu tating'onoting'ono, pomwe magiredi okwera ngati 50 μm kapena 100 μm amagwiritsidwa ntchito.

pa kusefedwa chisanadze kapena pamene kuthamanga kwapamwamba kumafunika

Kodi ma porous sintered stainless steel discs amapangidwa bwanji?

Porous sintered zosapanga dzimbiri zimbale amapangidwa kudzera njira zingapo:

1.Mafuta apamwamba azitsulo zosapanga dzimbiri amasankhidwa ndi kusakaniza molingana ndi kapangidwe kake ndi katundu.

2.Zitsulo zazitsulo zimapangidwira mu mawonekedwe ofunidwa ndi kukula kwake pogwiritsa ntchito zipangizo zapadera.

3.The compacted discs ndiye sintered mu olamulira mpweya kutentha kwambiri, makamaka pakati pa 1100 ° C ndi 1300 ° C.

4.Panthawi ya sintering, zitsulo zachitsulo zimagwirizanitsa pamodzi, kupanga mapangidwe olimba ndi pores ogwirizana.

5.The sintered zimbale ndiye anayendera, kutsukidwa, ndi mmatumba kuti akaperekedwe.

Kodi porous sintered stainless steel discs amagwiritsidwa ntchito bwanji?

Porous sintered zosapanga dzimbiri zimbale kupeza ntchito m'mafakitale osiyanasiyana, kuphatikizapo:

1.Chemical processing: Sefa ya zakumwa zowononga ndi mpweya

2.Pharmaceutical and biomedical: kusefera wosabala, kupatukana kwa cell, ndi kugwiritsa ntchito bioreactor

3.Chakudya ndi chakumwa: Kusefa kwamadzi ndi mpweya pokonza chakudya

4.Aerospace ndi chitetezo: Kusefa kwamadzimadzi a hydraulic ndi mafuta

5.Magalimoto: Kusefedwa kwa mafuta ndi zoziziritsa kukhosi

6.Kuchiza madzi: Kusefa kwa madzi ndi madzi oipa

Kodi ndimatsuka ndi kukonza bwanji ma disc a sintered stainless steel?

Porous sintered zosapanga dzimbiri zimbale akhoza kutsukidwa pogwiritsa ntchito njira zosiyanasiyana,

kutengera mtundu ndi mulingo wa kuipitsidwa:

1.Kubwerera m'mbuyo kapena kutsuka m'mbuyo: Kutembenuza njira yotuluka kuti itulutse ndikuchotsa tinthu totsekeredwa.

2.Ultrasonic kuyeretsa: Kugwiritsa ntchito mafunde apamwamba kwambiri kuti muchotse zonyansa

3.Chemical kuyeretsa: Kuviika ma discs mu njira yotsukira kuti amasule ndikuchotsa tinthu.

4.Kutsuka kwa ma circulation: Kupopa njira yoyeretsera kudzera m'ma disks mpaka atayera

Kuyeretsa ndi kukonza nthawi zonse kumathandiza kukulitsa moyo wa ma diski ndikuwonetsetsa kuti magwiridwe antchito amayenda bwino.

Kodi ma porous sintered stainless steel discs angasinthidwe kuti akwaniritse zofunikira zenizeni?

Inde, porous sintered zosapanga dzimbiri zimbale akhoza makonda kukwaniritsa zofunika zinazake.

Parameters monga diameter, makulidwe, zakuthupi,kusefera kalasi, ndi mawonekedwe akhoza kusinthidwa

zigwirizane ndi zosowa za ntchito zosiyanasiyana ndi njira.

Ma disks amathanso kuikidwa m'magulu osiyanasiyana azitsulo kapena osakhala azitsulo kuti agwiritse ntchito

Onani Mayankho Amakonda ndi HENGKO!

Kaya mukufuna zambiri kapena mukufuna chitsogozo pakusankha koyenera

sintered zosapanga dzimbiri zimbale, gulu lathu ndi wokonzeka kukuthandizani ndi mayankho angwiro fyuluta.

Lumikizanani nafe paka@hengko.comkwa chithandizo chamunthu payekha komanso upangiri waukatswiri wogwirizana ndi zosowa zanu.