-

Biopharmaceutical kuyeretsedwa ndi kusefera porous fyuluta mbale 10um 20um 50um

Porous fyuluta mbale ndi mtundu watsopano wa zinthu zapamwamba za porous zosefera zopangidwa ndi chitsulo chosapanga dzimbiri ufa kudzera mu sieving ufa, kuumba, sinterin ...

Onani Tsatanetsatane -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis ndi Galvanic Corrosion Imachepetsa Kusokoneza kwa RF Ndi Kupititsa patsogolo Ntchito Zamagetsi Kulandiridwa bwino kwa zida zanu za GPS, nyengo ...

Onani Tsatanetsatane -

sintered zitsulo zozungulira zosefera zakuya zopangira mafuta a cannabis

Kusefera Pakupanga kokhazikika kwa cannabinoids kusefera kwazinthu ndi gawo lofunikira. Kuchotsa sera, mafuta ndi mafuta ku winterization ambiri ...

Onani Tsatanetsatane -

Zosefera Zosapanga dzimbiri za Porous Metal Sheets SS316 Zosefera Kuphatikizika kwa Mafuta a Hydrogen

Zosefera Zachitsulo Zosapanga dzimbiri SS316 Zosefera Zosakanikirana ndi Gasi wa Hydrogen Tsegulani Kusiyanasiyana kwa Sintered Metal Elements ndi HENGKO! Meta yathu ya sintered...

Onani Tsatanetsatane -

Gasi Diffusion Zigawo Mapepala a MEAs, zitsulo zosapanga dzimbiri porous sintered / waya mauna ...

HENGKO zitsulo zosapanga dzimbiri zosefera zimapangidwa ndi sintering 316L ufa wa zinthu kapena multilayer zitsulo zosapanga dzimbiri ma mesh pa kutentha kwambiri. Iwo akhala...

Onani Tsatanetsatane -

Mipikisano wosanjikiza sintered zosapanga dzimbiri zitsulo mauna mbale fluidized bedi zida Distributor bot...

Chitsulo chosapanga dzimbiri mauna mbale kwa madzimadzi bedi Kulamulira kugawa gasi, kufala zinthu ufa, ndi ntchito fluidization wakhala chimagwiritsidwa ntchito mu indu ...

Onani Tsatanetsatane -

316 304 mbale yachitsulo chosapanga dzimbiri - Sintered porous zitsulo zosefera zachilendo

Zosefera zazitsulo zosapanga dzimbiri za HENGKO zimapangidwa ndi sintering 316L powder chuma kapena multilayer zitsulo zosapanga dzimbiri ma mesh pa kutentha kwambiri. Iwo akhala...

Onani Tsatanetsatane -

Zimbiri zosagwira ma microns 316L zitsulo zosapanga dzimbiri porous sintered fyuluta zitsulo mapepala / ...

Kufotokozera HENGKO zigawo za porous metal diffusion gasi ndiye chisankho chotsogola pakuchita bwino kwa electrolyzer ndi kugwiritsa ntchito ma cell amafuta. Uniform pa...

Onani Tsatanetsatane -

Easy Clean Micron Porous SUS Sintered 316L Stainless Steel Inline Metal Sheet Plate Rou...

The sintered porous zitsulo mapepala kukhala mkulu porosity analandira kuchokera zitsulo ufa ndi ufulu kufalitsa njira zotsatiridwa ndi sintering. The sintered structural ...

Onani Tsatanetsatane -

0.2 5 10 40 Micron porous sintered ufa zitsulo zosapanga dzimbiri 316L zitsulo mbale fyuluta kwa c ...

The porous zipangizo sintered mbale zopezedwa mu zigawo mwa kufalitsa kwaulere, compaction, ndi sintering zitsulo ufa amagwiritsidwa ntchito ngati theka-chinthu kupeza fi...

Onani Tsatanetsatane -

Mwamakonda 2 10 20 60 Micron Porous Sintered Stainless Stainless Steel 316L Metal Plate Sefa

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

5 10 30 60 90 microns ufa yaying'ono porous sintered zitsulo pepala fyuluta

Zosefera zazitsulo za Sintered zimagwiritsidwa ntchito kwambiri pochotsa tinthu takunja kuchokera kumitundu yosiyanasiyana yama media. Minda yayikulu yogwiritsira ntchito: gasi wamba, ...

Onani Tsatanetsatane -

HENGKO sintered zitsulo zosapanga dzimbiri 316 porous zitsulo kufalikira kwa mpweya zigawo zigawo fyuluta kwa ...

HENGKO chitsulo chosapanga dzimbiri sintered wire mesh fyuluta mbale imapangidwa kuchokera kumagulu angapo a mawaya olukidwa pagulu limodzi pogwiritsa ntchito sintering. Njira iyi...

Onani Tsatanetsatane -

Medical kalasi micron zitsulo zosapanga dzimbiri 316 316L waya mauna Mipikisano wosanjikiza mbale / chimbale fyuluta ...

Zosefera za ma mesh a HENGKO sintered wire mesh zili ndi zigawo 5 za waya za sintered zodzipangira zokha kuti zikhale zamphamvu zamakina komanso kukana kutentha kwambiri...

Onani Tsatanetsatane -

yunifolomu mphamvu sintered porous zitsulo micron fyuluta fluidizers bronze mkuwa mkuwa fizi...

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

Kuyenda kulamulira ndi kugawa madzimadzi sintered fyuluta mbale / pepala, ufa sintered porous ...

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

Porous zitsulo sintered porous mkuwa zosefera mbale/shiti kwa kuyenda ndi kulamulira phokoso

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

porous zitsulo fyuluta chimbale strainer micron sintered mkuwa fyuluta pepala

HENGKO imapanga zinthu zosefera mumitundu yambiri, makulidwe, ndi zokokera kuti zitha kufotokozedwa mosavuta ndi mawonekedwe ndi kasinthidwe...

Onani Tsatanetsatane -

hepa sintered bronze zitsulo zosapanga dzimbiri porous zitsulo fyuluta pepala makina mpweya / mafuta fyuluta

HENGKO imapanga zinthu zosefera mumitundu yambiri, makulidwe, ndi zokokera kuti zitha kufotokozedwa mosavuta ndi mawonekedwe ndi kasinthidwe...

Onani Tsatanetsatane -

Mwambo sintered ufa zitsulo fitler pepala microns porosity mkuwa fyuluta mapepala wat ...

HENGKO imapanga zinthu zosefera mumitundu yambiri, makulidwe, ndi zokokera kuti zitha kufotokozedwa mosavuta ndi mawonekedwe ndi kasinthidwe...

Onani Tsatanetsatane

Zofunika zazikulu za Porous Metal Plate:

Mbali zazikulu za mapepala azitsulo a porous ndi awa:

1.Kukhazikika Kwambiri:

Mapepala azitsulo amapangidwa kuchokera ku zipangizo zolimba monga chitsulo chosapanga dzimbiri, titaniyamu, kapena nickel alloys,

kupereka mphamvu zamakina kwambiri komanso kukana dzimbiri, kuvala, komanso kutentha kwambiri.

| Zakuthupi | Mphamvu zamakina | Kukaniza kwa Corrosion | Valani Kukaniza | Kulimbana ndi Kutentha | Mapulogalamu |

|---|---|---|---|---|---|

| Chitsulo chosapanga dzimbiri | Wapamwamba | Wapamwamba | Wapamwamba | Zabwino kwambiri (mpaka 800 ° C) | Kusefera, kukonza mankhwala, mafuta & gasi, mankhwala |

| Titaniyamu | Wapakati | Wapamwamba kwambiri | Wapakati | Zabwino kwambiri (mpaka 600 ° C) | Zamlengalenga, malo am'madzi, ntchito zamankhwala |

| Nickel Aloyi | Wapamwamba kwambiri | Zabwino kwambiri | Wapamwamba | Kupambana (mpaka 1000 ° C) | Kutentha kwambiri kusefera, kukonza mankhwala, kupanga mphamvu |

2.Precise Filtration Control:

Kukula kwa pore komwe kumayendetsedwa ndi kugawa kofanana kumalola kusefa kolondola, kumapereka mosasinthasintha

magwiridwe antchito osiyanasiyana.

3.Customizable Porosity:

Mapepala achitsulo a porous amatha kusinthidwa malinga ndi kukula kwa pore, mawonekedwe,

ndi kugawa, kupereka kusinthasintha kuti akwaniritse zofunikira zosefera kapena kuyenda.

4.High Permeability:

Ngakhale mphamvu zawo, porous zitsulo mapepala amalola mkulu permeability, kuonetsetsa

mayendedwe oyenda bwino a mpweya ndi zakumwa ndikusunga kusefa bwino.

5.Chemical Compatibility:

Mapepalawa amagwirizana ndi mitundu yambiri ya mankhwala, kuwapanga

yabwino kugwiritsidwa ntchito m'malo ovuta, kuphatikiza mafakitale opanga mankhwala ndi mankhwala.

6.Kutentha ndi Kupanikizika Kwambiri:

Zida zomwe zimagwiritsidwa ntchito muzitsulo za porous zimatha kupirira monyanyira

kutentha ndi kupsyinjika, kuonetsetsa kukhazikika ndi kudalirika pazofuna zofunikira.

7.Low Maintenance ndi Long Lifespan:

Mapepala achitsulo a porous amakhala olimba kwambiri komanso osamva kutsekeka,

kuchepetsa kufunika kokonza pafupipafupi ndi kusinthidwa, motero kumawonjezera moyo wawo wautumiki.

8.Thermal ndi Electrical Conductivity:

Kuphatikiza pa kusefera, mapepala achitsulo a porous amathanso kukhala ngati matenthedwe

ndi ma kondakitala amagetsi, kukulitsa ntchito zawo zosiyanasiyana.

Izi zimapangitsa kuti mapepala achitsulo a porous akhale abwino kwa ntchito zosefera, kuyendetsa bwino, zothandizira zothandizira,

ndi njira zolekanitsa m'mafakitale osiyanasiyana, monga zakuthambo, kukonza mankhwala, mankhwala,

ndi zomangamanga.

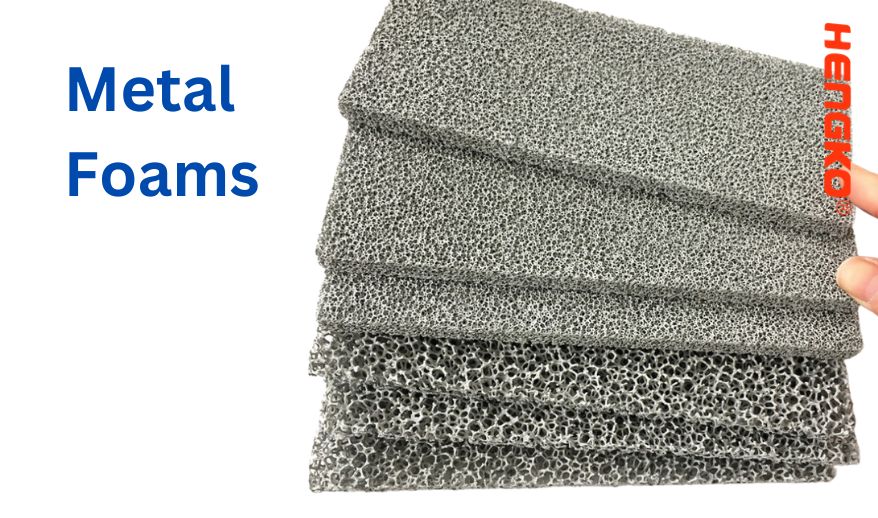

Mitundu ya Porous Metal Sheet ?

Kwenikweni pali mitundu iwiri ikuluikulu ya porous zitsulo mapepala mungapeze

mu msika wa porous metal sheet:

1. Zitsulo zopindika:

Izi amapangidwa ndi compacting ndi sintering zitsulo ufa. Pores mu mapepala awa nthawi zambiri

zolumikizana ndipo zimatha kusiyanasiyana kukula ndi mawonekedwe. Sintered zitsulo mapepala amagwiritsidwa ntchito nthawi zambiri ntchito

komwe kumafunikira mphamvu yayikulu komanso kusefera kwabwino, monga zosefera, zosinthira kutentha, ndi zochepetsera mawu.

2. Zida Zachitsulo:

Zitsulo zachitsulo zimapangidwa polowetsa thovu la gasi muzitsulo zosungunuka ndikuzilola kulimba.

Ma pores omwe ali m'mapepalawa amakhala otsekedwa, kutanthauza kuti samalumikizana. Zitsulo zachitsulo ndi

nthawi zambiri amagwiritsidwa ntchito m'malo opepuka komanso mwamphamvu kwambiri, monga muzamlengalenga ndi

ntchito zamagalimoto.

Nayi mitundu ina yazitsulo za porous:

1. Wolukidwa mawaya:

Ukonde wamtunduwu umapangidwa mwa kuluka pamodzi mawaya opyapyala. Kukula kwa pore mu mauna oluka

akhoza kulamulidwa ndi kukula kwa mawaya ndi ndondomeko yoluka. Wolukidwa waya mauna nthawi zambiri

zogwiritsidwa ntchitokumene kusefera ndi zinthu zoyenda bwino zimafunikira, monga zowonera ndi zosefera.

2. Chitsulo chowonjezera:

Tsamba lamtundu uwu limapangidwa podula chinsalu cholimba chachitsulo m'njira inayake ndikuchitambasula.

Pores muzitsulo zowonjezera nthawi zambiri amakhala atali komanso ngati diamondi. Zowonjezera zitsulo nthawi zambiri

zogwiritsidwa ntchitokumene kulemera kopepuka ndi mphamvu zabwino zimafunikira, monga alonda otetezeka ndi njira zoyendamo.

Kugwiritsa Ntchito Sintered Porous Metal Sheet

Sintered porous zitsulo mapepala ndi zosunthika zosefera TV chifukwa cha katundu wawo wapadera.

Nawa ena mwa mapulogalamu omwe mungagwiritse ntchito:

* Malo Otentha Kwambiri:

* Malo Owopsa a Chemical:

* Mapulogalamu Opanikizika Kwambiri:

* Kufunika Kowongolera Magawo Olondola:

* Reusability ndi Regenerability:

Komanso Nawa mafakitale ena omwe angapindule kwambiri pogwiritsa ntchito mapepala achitsulo a sintered porous mu makina awo osefera, inu

angayang'ane ngati zingakhale zabwino dongosolo kapena chipangizo?

* Chemical Processing - Kusefa zamadzimadzi zowononga ndi mpweya, komanso zoyambitsa kuchokera mumitsinje.

* Power Generation - Kusefera kwamphamvu kwambiri kwa mpweya m'mafakitale amagetsi.

* Makampani Azamankhwala - Kuwonetsetsa kuti zogulitsa ndi zoyera pochotsa mabakiteriya ndi tinthu tating'onoting'ono.

* Makampani a Chakudya & Chakumwa - Kusefera pakuwunikira zamadzimadzi, ndikuchotsa tinthu tosafunikira.

* Chithandizo cha Madzi - Kuthandizira njira zoyeretsera pochotsa zonyansa m'madzi.

Ponseponse, mapepala achitsulo opangidwa ndi sintered ndi chida chofunikira kwambiri pakusefera kwa mafakitale komwe kumafunikira kulimba, kukana kutentha kwambiri, kusefera kolondola, komanso kusinthikanso.

FAQ

1. Kodi aporous zitsulo pepala, ndipo amapangidwa bwanji?

A porous zitsulo pepala ndi mtundu wa zinthu zodziwika ndi permeable dongosolo, wopangidwa ndi

olumikizidwa pores kapena voids mu unyinji wake. Mapepalawa amapangidwa makamaka kudzera

njira yotchedwa sintering. Sintering imaphatikizapo kuphatikizira ufa wachitsulo mu nkhungu kenako ndikuwotha

ili pansi pa malo ake osungunuka. Kuchiza kutentha kumeneku kumapangitsa kuti tinthu ting'onoting'ono tigwirizane popanda kukhetsa madzi,

kupanga mapangidwe olimba okhala ndi porosity yoyendetsedwa bwino.

Njirayi imalola kupanga mapepala okhala ndi kukula kwa pore, mawonekedwe, ndi kugawa,

zokonzedwa kuzinthu zinazake. Mapepala osapanga dzimbiri a Sintered, mwachitsanzo, amagwiritsidwa ntchito kwambiri chifukwa cha

makina awo abwino kwambiri, kukana dzimbiri, komanso kukhazikika kwamafuta.

2. Kodi ntchito zazikulu zazitsulo zosapanga dzimbiri za sintered ndi ziti?

Sintered zitsulo zosapanga dzimbiri zimagwiritsidwa ntchito pazinthu zosiyanasiyana chifukwa cha kusinthasintha komanso kulimba.

Zina mwazofunikira kwambiri ndizo:

*Sefa:

Amagwiritsidwa ntchito muzinthu zonse zosefera gasi ndi zamadzimadzi, amachotsa bwino tinthu tating'onoting'ono

chifukwa cha kukula kwake kwa pore.

* Kuphatikizika ndi kusanja:

Zoyenera kuchita ndi gasi-zamadzimadzi, mpweya, ndi njira zofusira,kumene kulamulidwa

kukula kwa thovu ndikofunikira.

*Fluidization:

Amagwiritsidwa ntchito m'mabedi amadzimadzi pazinthu zosiyanasiyana zamankhwala, kuthandizira kufananizakugawa

mpweya kudzera muzamadzimadzi kapena ufa.

* Chitetezo cha Sensor:

Imateteza zigawo zokhudzidwa m'malo ovuta, kuteteza kuipitsidwa

pamene kulola kuyanjana koyenera kwa chilengedwe.

* Kubwezeretsa ndi Chithandizo cha Catalyst:

Amapereka nsanja yabwino kwambiri yopangira zida zothandizira, kuwongolera

zochita za mankhwala pamene kulola kuchira mosavuta kwa zothandizira zamtengo wapatali.

3. Kodi mumadziwa bwanji kukula kwa kabowo koyenera kuti mugwiritse ntchito?

Kuzindikira kukula koyenera kwa pore kwa ntchito inayake kumaphatikizapo kulingalira

zinthu zingapo, kuphatikizapo chikhalidwe cha madzi kapena mpweya kukonzedwa, mitundu ya

particles kapena zoipitsa kuchotsedwa, ndi kufunika otaya mlingo. Kwa mapulogalamu osefa,

kukula kwa pore kumasankhidwa kukhala kocheperako pang'ono kuposa tinthu tating'ono kwambiri tomwe timafunikira

kuti zisefedwe. Pazogwiritsa ntchito kufalikira kwa gasi kapena sparging, kukula kwa pore kumakhudza

kukula kwa thovu opangidwa, zomwe zingakhudze kwambiri dzuwa la ndondomekoyi.

Kufunsana ndi opanga mapepala azitsulo a porous ngati HENGKO atha kupereka zidziwitso kutengera

zambiri ndi ukatswiri luso, kuonetsetsa kusankha mulingo woyenera pore kukula

pa ntchito iliyonse yoperekedwa.

4. Ndi maubwino otani omwe zitsulo zosapanga dzimbiri sintered amapereka kuposa zipangizo zina?

Mapepala osapanga dzimbiri a Sintered amapereka maubwino angapo kuposa zida zina, kuwapanga kukhala a

kusankha kokonda pazantchito zambiri zamafakitale:

* Kukhalitsa:

Mphamvu zawo zapamwamba komanso kukana kuvala ndikung'amba zimatsimikizira moyo wautali wautumiki pansi pazovuta.

* Kulimbana ndi Corrosion:

Chitsulo chosapanga dzimbiri chosakanizidwa ndi dzimbiri ndilabwino kuti chigwiritsidwe ntchito m'malo ovuta kwambiri kapena

kumene kumakhala kofala kukhudzana ndi zinthu zowononga.

* Kukhazikika Kwambiri Kutentha:

Amatha kupirira kutentha kwambiri popanda kunyozeka, kuwapanga kukhala oyenera kugwiritsidwa ntchito posinthanitsa kutentha,

zosefera kutentha kwambiri, ndi ntchito zina amafuna bata matenthedwe.

* Kugwirizana kwa Chemical:

Chitsulo chosapanga dzimbiri chimagwirizana ndi mankhwala osiyanasiyana, kuchepetsa chiopsezo cha kuwonongeka kwa zinthu

ndi kuipitsidwa.

* Kuyeretsa ndi Kusabala:

Malo awo osalala, opanda pobowa amatha kutsukidwa mosavuta komanso osawilitsidwa, ndikofunikira pakupanga mankhwala.

komanso kugwiritsa ntchito zakudya ndi zakumwa.

5. Kodi mapepala achitsulo osapanga dzimbiri angasinthidwe kuti agwiritse ntchito mwapadera?

Inde, zitsulo zosapanga dzimbiri zosapanga dzimbiri zitha kusinthidwa kuti zikwaniritse zofunikira zapadera.

Kusintha mwamakonda kungaphatikizepo kusiyanasiyana kwa pore, makulidwe, kukula kwa pepala, ndi mawonekedwe, komanso kuphatikiza

za ma alloying apadera kuti apititse patsogolo zinthu zina monga conductivity kapena kukana kutentha.

Opanga ngati HENGKO amakhazikika pogwira ntchito limodzi ndi makasitomala kuti apange ndikupanga zitsulo zowoneka bwino.

mayankho omwe amakwaniritsa ndendende zomwe amafunikira komanso momwe amagwirira ntchito zomwe amafunikira pazofunsira zawo.

Mulingo woterewu umatsimikizira kuti chomaliza chikhoza kuchita bwino pamalo omwe akufuna,

kaya zikuphatikiza zosowa zapadera zosefera, kukonza kwapadera kwamankhwala, kapena ntchito ina iliyonse yamakampani.

Lumikizanani ndi HENGKO

Mwakonzeka kukweza ntchito yanu yamafakitale ndi ma bespoke porous metal solutions?

Tumizani kwa ife paka@hengko.comndipo tiyeni tisinthe zovuta zanu kukhala zopambana.