Kodi Sintered Metal ndi chiyani?

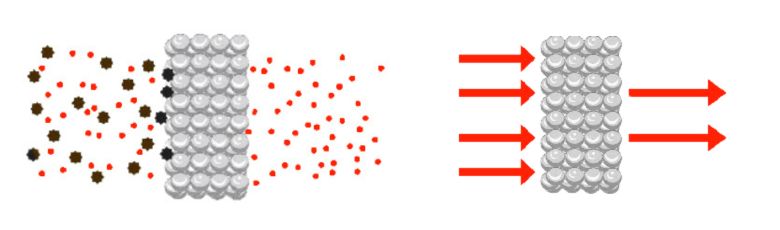

Kodi Sintered Filter Working Principle ndi chiyani?

Mwachidule kunena, Chifukwa cha chimango chokhazikika,zosefera zitsulo za sinteredndi imodzi mwazinthu zabwino zosefera

masiku ano. Komanso, kutentha kwambiri kwa zida zachitsulo, kuthamanga kwambiri, komanso kukana dzimbiri kungakuthandizeni

Malizitsani ntchito zosefera mosavuta m'malo ovuta, Kulekanitsa ndi kusefa zonyansa zochulukirapo

simukusowa kapena kukuthandizani kuchotsa mpweya chiyero apamwamba kapena zamadzimadzi ntchito yanu, ndipo ngati inunso kuyang'ana

fakitale yeniyeni ku OEM sintered zitsulo fyuluta dongosolo lanu kusefera, chonde onani apa kupeza

ndiOpanga Zosefera Zapamwamba Zamakampani.

Mwina Simuyenera kumva mawu awa kwambiri pamoyo wanu watsiku ndi tsiku.

Koma masiku ano, sintered zitsulo ntchito kwambiri m'mafakitale osiyanasiyana, sintered zitsulo wayamba kukhala.

ndiukadaulo wofunikira pakupanga kwina.

NdiyeChomwe Ndi Chitsulo Chokhazikika?

Kwenikweni, ndi nthambi yamakampani opanga zitsulo, mwachidule, ndi chitsulo chosapanga dzimbiri cha 316L.ufa kupyolera mu nkhungu

kuumba, kutentha kwambiri sintering mu mawonekedwe ndi ntchito ya ndondomeko kuti tiyenera.

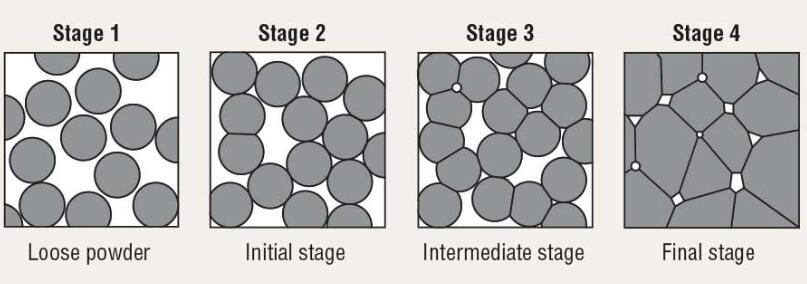

Kenako, Choyamba, sintered.Kodi sintered ndi chiyani?

Sintering ndi njira yophatikizirandi kupanga misa yolimba yazakuthupi

ndi kutentha kapena kupsyinjika popanda kusungunuka mpaka kumadzimadzi. Sintering ndi gawo lanjira yopangira ntchito

ndi zitsulo, ceramics,mapulasitiki, ndi zipangizo zina.Wikipedia

Monga Wikipedia ikufotokozera, zida zamitundu yambiri zimatha kusinthidwa, ndipo zinthu zosiyanasiyana zomwe zidapangidwa zimakhala nazo

zosiyanamapulogalamu. Ndiye apa timakondakulankhula zambiri za sintered zitsulo.

1. Kusefera ndi Kupatukana 2. Zoletsa zamadzimadzi

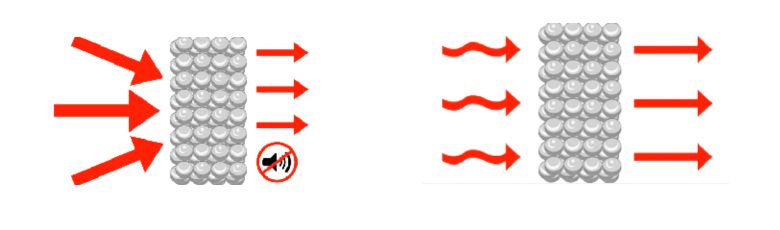

3. Kuchepetsa phokoso 4. Kuthamanga kokhazikika

MbiriZithunzi za Sintering Metal

Who Inventions the sintering ndikuyamba kugwiritsa ntchito zinthu zosinthidwa?

Malinga ndi mbiri yakale, njira yopangira sintering idawonekera pakusintha kwachiwiri kwa mafakitale m'zaka za zana la 18

ku Swedenndi Denmark. Chitsulo chosungunuka chinaliopezeka posungunula m’migodi ya malasha. Koma mpaka 1980, anthu

anayamba kugwiritsa ntchitosintered zitsulo ku mafuta osefa. Ndipo mu 1985, woyamba adagwiritsa ntchito HyPulse®luso kusefera kwa

kusefera kwamafuta kosalekeza.

Chifukwa chake, mutha kuyang'ana motsatira, pali nthawi yayikulu ya 3-kukula.

1.Chiyambi Chakale

*M'badwo wa Bronze:

Umboni wakale kwambiri wamachitidwe ngati sintering unayambira mu Bronze Age, komwe kunali zinthu zachitsulo

mwina amapangidwa ndi kutentha ndi kufinya zitsulo ufa.

*Nyengo za Iron:

Njira zopangira chitsulo, kuphatikiza kugwiritsa ntchito chitsulo chotenthedwa ndi choponderezedwa, mwina adaphatikiza

zinthu za sintering.

2.Kusintha kwa Industrial ndi Zotukuka Zoyambirira

* Zaka za zana la 19:

Kusintha kwa Industrial Revolution kunachititsa chidwi chowonjezereka mu njira zopangira zitsulo. Metallurgy ufa,

kalambulabwalo wa sintering, anayamba kuonekera ngati njira yopangira zinthu zachitsulo kuchokera ku zipangizo zaufa.

*Kumayambiriro kwa zaka za zana la 20:

Kupita patsogolo kwa metallurgy ndi sayansi yazinthu kunapangitsa kuti pakhale chitukuko chowonjezereka muukadaulo wa sintering.

Kupanga zosefera zitsulo zokhala ndi porous ndi ma bearings pogwiritsa ntchito njira za sintering kudakhala kofala.

3.Modern Era ndi Tekinoloje Zopita patsogolo

*Mid-20th Century:

Tekinoloje ya Sintering idakula kwambiri mkati mwa zaka za zana la 20, motsogozedwa ndi kupita patsogolo

mu powder metallurgy ndi sayansi yazinthu. The chitukuko cha mkulu-ntchito sintered zipangizo kwa

ntchito zazamlengalenga, zamagalimoto, ndi mafakitale zidakhala chidwi.

* Chakumapeto kwa 20th ndi koyambirira kwa 21st Century:

Chakumapeto kwa zaka za m'ma 20 ndi koyambirira kwa zaka za zana la 21 zidawonetsa luso laukadaulo la sintering. Chitukuko

Njira zotsogola za sintering, monga selective laser sintering (SLS) ndi jetting binder, zidakulitsa mtunduwo.

za zipangizo ndi maonekedwe ovuta omwe akanakhoza kupangidwa.

Mapulogalamu Amakono

*Magalimoto:

Zida za Sintered zimagwiritsidwa ntchito kwambiri pazinthu zamagalimoto, kuphatikiza magiya, mayendedwe, ndi zosefera.

Makhalidwe awo, monga mphamvu, kulimba, ndi porosity, amawapangitsa kukhala abwino kwa ntchito zovuta.

*Zamlengalenga:

Zida zopangira sintered zimagwiritsidwa ntchito muzamlengalenga chifukwa cha zopepuka, zamphamvu kwambiri.

Amapezeka m'magawo monga ma turbine blade, ma nozzles amafuta, ndi zosinthira kutentha.

*Zida Zachipatala:

Zida za Sintered zimagwiritsidwa ntchito pazida zosiyanasiyana zamankhwala, kuphatikiza ma implants, ma prosthetics, ndi zida zamano.

Ma biocompatibility awo ndi zinthu zomwe mungasinthe zimawapangitsa kukhala oyenera kugwiritsa ntchito izi.

*Mapulogalamu amakampani:

Zida za Sintered zili ndi ntchito zambiri zamafakitale, kuphatikiza kusefa, zamagetsi, ndi kusungirako mphamvu.

Kusinthasintha kwawo komanso magwiridwe antchito amawapangitsa kukhala ofunika m'mafakitale osiyanasiyana.

Mapeto

Komabe, ukadaulo wa Sintering wasintha kwambiri pazaka mazana ambiri, kuyambira pomwe adachokera mpaka kumagwiritsidwe ake amakono.

Kupyolera mukupita patsogolo kosalekeza kwa sayansi ya zida ndi njira zopangira, zida zopangira sintered zakhala

zofunikira m'mafakitale osiyanasiyana, zomwe zimathandizira kupita patsogolo kwaukadaulo ndi luso.

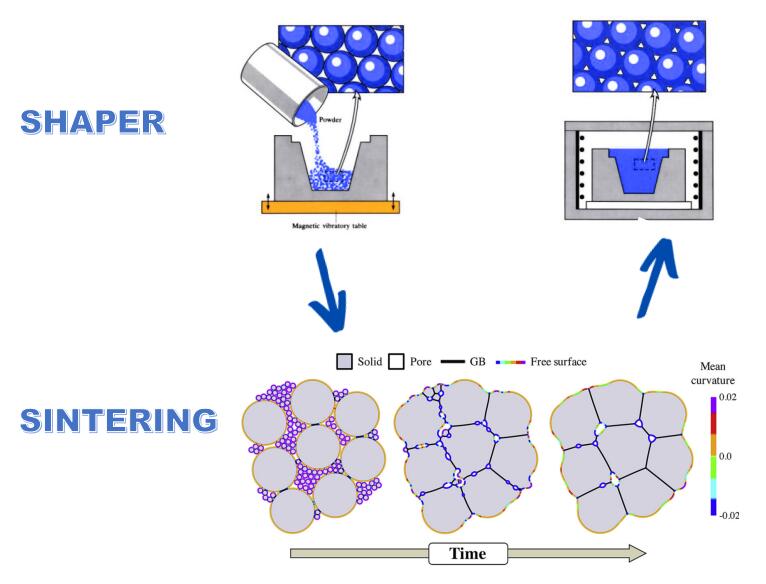

Ndiye Kodi Sefa ya Sintered Metal ndi chiyani?

Tanthauzo losavuta la fyuluta yachitsulo ya sintered:

Ndi fyuluta yachitsulo yomwe imagwiritsa ntchito tinthu tating'ono ting'onoting'ono tofananakukula kwa tinthukupangidwa ndi stamping,

mkulu-kutentha sintering ndondomeko. Sintering ndi njira yazitsulo pogwiritsa ntchito ufa-kakulidwematupi a

zitsulo zosiyanasiyana ndi aloyi pambuyo kusindikiza.

Metallurgy imachitika mwa kufalikira pa kutentha pansi pa malo osungunuka a ng'anjo zotentha kwambiri.

Zitsulo ndi aloyiamagwiritsidwa ntchito mofala masiku anomonga aluminium, mkuwa, faifi tambala, mkuwa, chitsulo chosapanga dzimbiri,

ndi titaniyamu.

Pali njira zosiyanasiyana zomwe mungagwiritse ntchito kupanga ufa. Zimaphatikizapo kugaya, atomization,

ndi kuwonongeka kwa mankhwala.

Zomwe Sintering Njira Yopangira Zosefera za Metal

Ndiye, kotero apa, ife timakonda fufuzani ndondomeko mwatsatanetsatane za Metal fyuluta kupanga. ngati mukufuna, chonde onani pansipa:

1.) Kodi Sintering ndi Chiyani, Chifukwa Chiyani Mukugwiritsa Ntchito Sintering?

Tanthauzo losavuta la sintering ndi ufa wachitsulo umalumikizidwa pamodzi ndi kutentha kwambiri ndi njira zina

moduli yomwe mukufuna.Mu ma micron osiyanasiyana, palibe malire pakati pa tinthu tating'onoting'ono ta chitsulo,

chifukwa chake tikhoza kulamulira mtunda wa pore

kudzera munjira yopangira.

The porous cartridge of the sintering process amapereka mawonekedwe okhazikika achitsulo ndipo amapereka

zinthu ndintchito ya kusefera mwamphamvu.

2.)3-WamkuluMasitepe a Sintered Metal Filter Manufacturing

A: Gawo loyamba ndikupeza Power Metal.

The zitsulo ufa, Mukhoza kupeza zitsulo ufa pogaya, atomization, kapena kuwonongeka mankhwala.

Mutha kuphatikiza chitsulo chimodziufa ndi chitsulo china kuti apange aloyi panthawi yopanga,

kapena mutha kugwiritsa ntchito ufa umodzi wokha. Ubwino wa sintering ndi umenewosichisintha thupi

katundu wa chuma chuma. Njirayi ndi yophweka kwambiri moti zinthu zachitsulo sizimasinthidwa.

B: Kupondaponda

Gawo lachiwiri ndikutsanulira ufa wachitsulo mu nkhungu yokonzekera kale momwe mungapangire fyuluta.

Msonkhano wa fyuluta umapangidwa m'chipindakutentha ndi pansi pa sitampu. Kuchuluka kwa kukakamizidwa kogwiritsidwa ntchito

zimatengera zitsulo zomwe mukugwiritsa ntchito, chifukwa zitsulo zosiyanasiyana zimakhala ndi mphamvu zosiyana.

Pambuyo pa kukhudzidwa kwakukulu, ufa wachitsulo umapangidwira mu nkhungu kupanga fyuluta yolimba.Pambuyo pa

ndondomeko yamphamvu kwambiri, mungatheikani fyuluta yachitsulo yokonzedwa mu ng'anjo yotentha kwambiri.

C: Kutentha Kwambiri Sintering

Muchikozyano, tusyoonto tusyoonto tusyoonto buyo tweelede kuzumanana kuba acilongwe cini-cini atalaa mbocibede.

Monolith uyu ndi wamphamvu,cholimba, ndi porous fyuluta ngati chitsulo.

Mukhoza kulamulira porosity wa fyuluta ndi ndondomeko malinga ndi otaya mlingo wa mpweya kapena madzi kuti asasefedwe.

Dzina la sintered media grade ndi lofanana ndi pore wapakati, kapena kukula kwapakati kwa fyuluta.

Sintered zitsulo media ndizoperekedwa mu giredi 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 ndi 100. The kusefera mlingo mu

madzi a pa TV giredi 0.2 mpaka 20 ali pakati pa 1.4 ndi 35 µmmtheradi. Masefedwe amtundu wa gasi

kuchokera ku 0.1 mpaka 100 µm mtheradi.

Chifukwa Chiyani Kugwiritsa Ntchito Chitsulo Sintering Kupanga Zosefera?

Ili ndi funso labwino, bwanji kugwiritsa ntchito chitsulo kupanga fyuluta?

Yankho lake ndi losavuta, ndipo ngakhale pali zifukwa zambiri, mtengo wake ndi wofunika kwambiri.

Chifukwa Chiyani Mtengo?

Inde, chitsulo chosungunuka chimakhala chokhazikika ndipo chimatha kugwiritsidwanso ntchito, kuyeretsa, ndi kugwiritsidwa ntchito nthawi zambiri.

Komanso, zitsulo zosiyanasiyana zimakhala ndi mphamvu zokhazikika zakuthupi ndi zamankhwala ndipo siziwonongeka mosavuta.

Ichi ndichifukwa chake Zosefera zambiri za Sintered zimagwiritsidwa ntchito m'mafakitale osiyanasiyana.

Zosankha Zakuthupi ndi ZotaniZosefera za Sintered?

Ndi kupita patsogolo kosalekeza kwaukadaulo wauda zitsulo, pali zosankha zambiri

zida zosefera zitsulo za sintered,

Mutha kusankha kuchokera kuzitsulo zina zambiri ndi ma aloyi kuti mukwaniritse zofunikira zapadera

kutentha ndi kuthamanga, dzimbirikukana etc , Main zitsulo zipangizo monga:

-

Fyuluta yachitsulo chosapanga dzimbiri; 316L, 304L, 310, 347 ndi 430

-

Bronze

-

Inconel® 600, 625 ndi 690

-

Nickel200 ndi Monel® 400 (70 Ni-30 Cu)

-

Titaniyamu

-

Aloyi

Zitsulo zowonjezereka zidzagwiritsidwa ntchito m'tsogolomu.

8-Ubwino Waukulu wa Sintered Metal Filter

1. ) Kukana dzimbiri

Zitsulo zambiri zimagonjetsedwa ndi dzimbiri, monga sulfides, hydrides, oxidation, etc.

2. ) Kuchotsa kothandiza kwambiri kwa zonyansa

Kusintha porosity ya cartridge kumadzimadzi kumatanthauza kuti mutha kukwaniritsa zabwino

kusefera mukufuna ndi kupeza amadzimadzi opanda zonyansa. Komanso, popeza fyulutayo sichita dzimbiri,

zomwe fyuluta sizimatengera kupezekaza zoipitsa mu madzimadzi.

3. ) High Thermal Shock

Panthawi yopanga, kutentha kwakukulu kumapangidwa, ndi zinthu zakuthupi za

zitsulo izi zimathandiza kuyamwakutenthedwa kwakukulu kwa fyuluta. Chifukwa chake, mutha kugwiritsa ntchito izi

zosefera mu osiyanasiyana ntchito kutengeramatenthedwe osiyanasiyana a ntchito.

Kugwedezeka kwakukulu kwamafuta kumapangitsanso kusefa kwamadzimadzi popanda kudandaula

kutentha kwa ntchito.

4,) Kuthamanga Kwambiri Kutsika

Asintered zitsulo fyulutaakhoza kusunga kuthamanga kwamadzimadzi mu ntchito yanu, motero kuonetsetsa

pazipita ntchito.

Kutsika pang'ono kumatha kuwononga pulogalamu yanu.

5. ) Kutentha ndi Kukaniza Kupanikizika

Mutha kugwiritsa ntchito fyulutayi pamapulogalamu omwe ali ndi kutentha kwambiri komanso kupanikizika popanda

kuda nkhawa ndi zinthu zanu zosefera.

Kugwiritsa ntchito zosefera zitsulo za sintered popanga zochita za mankhwala ndi mpweya

mankhwala zomera zimatsimikizira inupezani zotsatira zabwino kwambiri zosefera.

6. ) Cholimba komanso Chosamva Kusweka

Ubwino wina wogwiritsa ntchito fyuluta yachitsulo ya sintered ndikuti ndi yamphamvu komanso yosamva

kusweka.

Panthawi yopanga, kugwirizanitsa zitsulo kumachitika pa kutentha bwino

pansi pa malo osungunuka.

The chifukwa mankhwala ndi amphamvu sintered zitsulo fyuluta kuti akhoza kupirira zosiyanasiyana

malo ovuta.

Mwachitsanzo, mutha kuyigwiritsa ntchito pamapulogalamu omwe amafunikira kukangana popanda kuwopa kusweka.

7.) Kulekerera Kwabwino

Kulekerera bwino kumatanthauza kuti fyuluta yanu yachitsulo yosungunuka imatha kusefa madzi anu popanda kuchitapo kanthu.

Sefa yanu ikatha, fyuluta yachitsulo ya sintered imasunga mawonekedwe ake.

Komabe, zingathandize ngati mutaonetsetsa kuti chitsulo chomwe mwasankha pa fyuluta yanu sichidzatero

chitani ndi madzimadzi omwe mukusefa

8.) Zotheka zosiyanasiyana za Geometric

Makatiriji a Sintered amakulolani kuti musangalale ndi zosankha zingapo za geometric. Mutha kukwaniritsa

uku ndikulowetsa ufamu utoto pakupanga.

Chikombole ndi chomwe chiyenera kupanga fyuluta yanu.

Chifukwa chake, ndinu omasuka kugwiritsa ntchito mapangidwewo malinga ndi zomwe mukufuna.

Mwachitsanzo, ngati pulogalamu yanu ikufuna fyuluta yaying'ono, mutha kusintha kapangidwe kake mosavuta

kupeza chaching'ono

sintered zitsulo fyuluta.Momwemonso, ngati pulogalamu yanu ili ndi mapangidwe apadera, mutha mosavuta

kusintha kapangidwe kakenkhungu pakupanga.

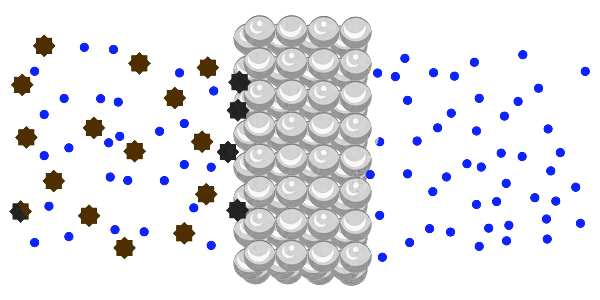

Kodi Zosefera za Sintered Metal Zimagwira Ntchito Motani?

Vutoli likhoza kunenedwanso kuti ndilo ndondomeko yogwira ntchito yazitsulo zazitsulo za sintered. Anthu ambiri amaganiza

kuti funso ilizovuta kwambiri kuyankha, ndipo si.Mutha kudabwa ndi izi, koma mwina inu

sindikhala nditawerenga kufotokoza kwanga.

Zosefera zachitsulo za Sintered ndizosefera zothandiza kwambiri. Kutolere zoipitsa kumachitika padziko

madzimadzi; pamene amadzimadzi amadutsa zitsulo fyuluta, ndizazikulu particles ndi zoipitsa adzakhala

anasiya mbali imodzi ya katiriji, koma pamenekusankha bwino kusefera mlingo wanu madzimadzi, inu

muyenera kuonetsetsa kutiimathanso kusefa zofunika.

*Zofunikira izi zikuphatikiza

1. Kuyipitsa Kusunga Backwash Kutha

2. Pressure Drop

Kuti muchepetse kuthamanga, muyenera kuganizira zinthu zingapo.

Zinthu izi zikuphatikizapo

AKukhuthala kwamadzimadzi, kuthamanga kwamadzi komwe kumadutsa muzosefera, ndi mawonekedwe oipitsidwa.

BMakhalidwe oyipa amaphatikiza mawonekedwe a tinthu, kachulukidwe, ndi kukula kwake.

Ngati choipitsacho chili cholimba komanso chokhazikika, kupanga keke wandiweyani, ndiye kusefera kwapamtunda ndikoyenera.

*Kuchita Bwino kwa Sintered Metal Sefa Zimatengera

1.kupanikizika kowonjezereka kumatsika mpaka pamene kupanikizika kotheratu kumafika.

2. kuyenda kosalekeza kwa madzimadzi.

Mukhoza kukwaniritsa mapeto mwa kukulitsa zonyansa zomwe zimawonjezeka mpaka pamene kuthamanga kwamadzimadzi kumatsika.

Kupanikizika uku kumatsika mosalekeza mpaka dontho lalikulu la viscosity yopatsidwa ndi kufunikira kwa liwiro lakuyenda kumafika.

Nkhani ina yofunika ndikutsuka kumbuyo kwa fyuluta, yomwe imachitidwa ndi kukanikiza gasi pazenera komanso mwachangu.

kutsegula valavu yotulutsa backwashmonga kuchapa msana kumachitika.

A high reverse instantaneous pressure differential ndizopangidwa. Imachotsa bwino zonyansa kuchokera ku fyuluta

chinthu pamwamba. Zosinthakutuluka kwa madzi oyera kudzera muzosefera kumachotsa zowononga ndikuziwongolera

kunja kwa fyuluta.

Kukwera kosalekeza kwa kutsika kwamphamvu kukuwonetsa kugawa kosasinthasintha komanso kofanana kwa kukula koyipa.To

kukwaniritsa zogwirizanakugwira ntchito, muyenera kuwonetsetsa kuti kutsika kwamphamvu kwa chinthu chosefera ndikokhazikika.Ngati kutentha

kusintha kwamadzimadzi kumakhudzakukhuthala kwa madzimadzi. Pamenepa, kuthamanga kutsika kudutsa fyulutaelement idzatero

onjezerani komanso osakwaniritsa zosefera.

Choncho, muyenera kusunga kutentha ntchito fyuluta pa ndondomeko kusefera ndi

onetsetsanikutentha kwa madzimadzi ndi kuthamanga.Poyeretsa fyuluta, muyenera kutsatira

ndondomeko yoyenera kutsuka msana.

Kodi Zosefera za Sintered Metal Zimagwira Ntchito Motani?

Mutha kumvetsetsa mukayang'ana zotsatiraziChiwonetsero cha mfundo zogwirira ntchito

Monga kutsatira chachikulu8 - Mitunduwa Thentchito mfundo kusefera zitsulo, ndikuyembekeza kukuthandizani

kumvetsa zambiriza bwanjiSintered zitsulo Zosefera zingathandizekwa kusefera madzi, gasi ndi mawu.

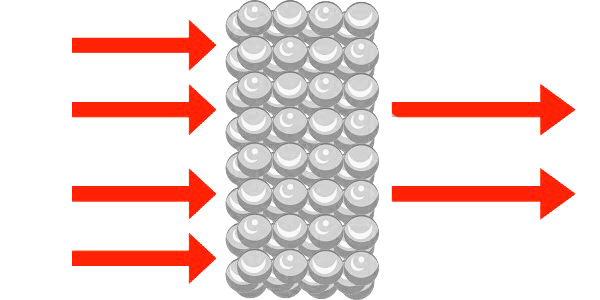

1.) Kusefera kwamadzi & Gasi / Kupatukana

Zosefera za Sintered Metal zimatha kuchepetsa kapena kuchotseratu zinthu zina kuchokera ku gasi kapena sing'anga yamadzi.

Tinthu tating'ono tingathePhatikizani koma osangokhala ndi tinthu tating'onoting'ono (matope, zitsulo zachitsulo, mchere, etc.),

algae, mabakiteriya, bowa spores, ndi zosafunikamankhwala/biological zoipitsa. Zitsulo zosefera pore kukula kwake

akhoza kukhala osiyanasiyana kuchokera ku 0.2 µm - 250 µm.

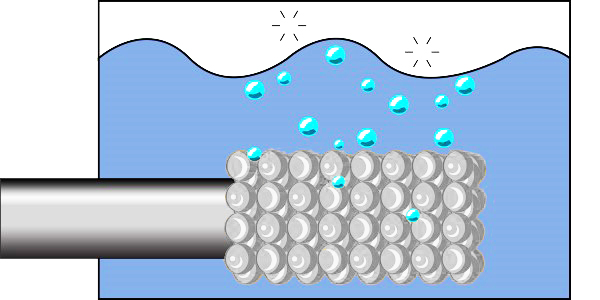

2.)Sparger

Zina mwa Mapulogalamu Othandizira:

Soda Carbonization

Mowa Carbonization

OxygenKuchotsa Mafuta Odyera

Sparging ndiko kuyambitsa kwa gasi kukhala madzi. Amagwiritsidwa ntchito mwina kuchotsa mpweya wosafunikira wosungunuka

(kuchotsa mpweya) kapenamadzi osungunuka osungunuka. Itha kugwiritsidwanso ntchito kuyambitsa mpweya kukhala madzi (carbonization).

Traditional sparging analenga thovundi m'mimba mwake 6 mm. PM fyuluta sparging amalola ngakhale yaying'ono

kuwira m'mimba mwake, motero kuonjezera padziko derathovu kumapangitsa kuti srging imayenera

kugwiritsa ntchito mwa kuchepetsa nthawi ya ndondomeko.

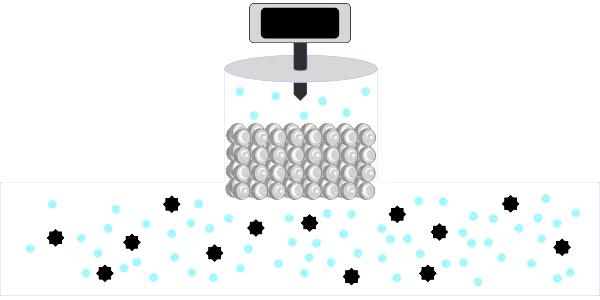

3.) Mpweya Wopumira

Zosefera zachitsulo za Sintered zimagwiritsidwanso ntchito ngati mpweya wopumira mu masilinda, ma gearbox, manifolds, ma hydraulic system,

nkhokwe, ndi zinamachitidwe. Mpweya wopumira umalola kufananiza kwamphamvu ndi mpweya / mpweya kulowa ndi kutuluka mudongosolo

potsekereza tinthu tating'onoting'onokulowa mu dongosolo. Zosefera zachitsulo zimatha kutsukidwanso kuti zichotse tinthu tating'onoting'ono

nkhani, kuwapatsa moyo wautali ngati mpweyavent kuposa zosefera zina.

4.) Chitetezo cha Sensor

Zosefera za Sintered Metal zimathanso kuteteza zida zamagetsi ngati chivundikiro, monga ma thermometers,

masensa osiyanasiyana,kiyizigawo za machitidwe azachipatala, ndi zinthu zina tcheru zochokera m'madzi,

madzi, zinyalala, fumbi, ndikusinthasintha kwamphamvu.

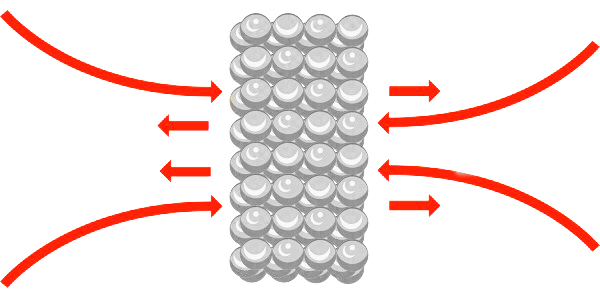

5.) Kuwongolera (Kuthamanga / Kuchepetsa)

Fyuluta yapadera ya sintered imatha kuwongolera kayendedwe ka mpweya, mpweya, vacuum, ndi kayendedwe ka madzimadzi. The

yunifolomu ya fyulutapore saizikulola kusasinthasintha, kubwereza koyenda komanso kuteteza ma valve, masensa,

ndi china chilichonse chapafupimu dongosolo kuchokerazoipitsa. Kuwongolera koyenda kumagwiritsidwa ntchito motere

ntchito monga nthawi ya pneumatic, kuwongolera gasizinthu, ndi kuchedwa kwa nthawizinthu mu

ntchito zamagalimoto.

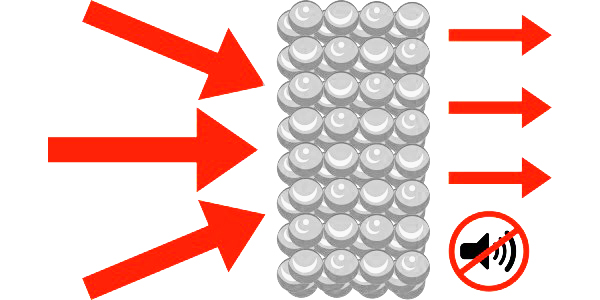

6.) Ma Silencers a Air Exhaust

Zosefera za Sintered zimathanso kuwotcherera kapena kulumikizidwa ndi cholumikizira chilichonse chofunikira, kuwalola kuti azigwira ntchito ngati cholumikizira.

exhaust silencer.Zosefera sizingateteze ma solenoids ndi manifolds ku zonyansa mkati

dongosolo komanso amachepetsa phokosomlingo wa kutopa kuchokera ku dongosolo. Zosefera zotulutsa mpweya

komansokutsitsa mpweya wotuluka kuchokera ku dongosolo, zomweamachepetsa zonyansa wafting, Kuteteza

chilengedwe.

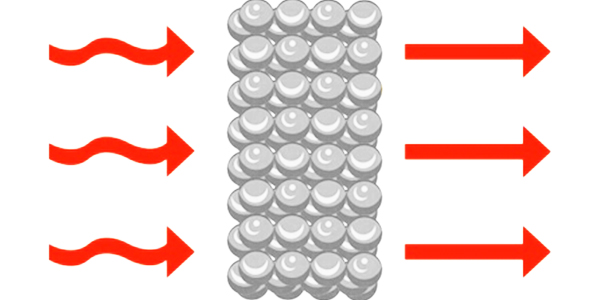

7.) Flow / Pressure Equalization

Zosefera za Sintered zimatha kufananiza ndikuwongolera kuthamanga kwa makina ndi kuthamanga kwake. Kufanana kumateteza

machitidwe motsutsana ndi kuphulikayamadzimadzi ndikupanga kuyenda kofanana pamene gasi kapena madzi akudutsa

pores yunifolomu.

Kodi Zosefera za Sintered Zimagwiritsidwa Ntchito Bwanji?

Pa funso ili, Kwenikweni anthu ambiri adzafunsa Kodi ntchito Sintered zitsulo Zosefera?

Pambuyo povuta chotere, kodi makatiriji osefera zitsulo adzagwiritsidwa ntchito kuti?

Chowonadi ndi chakuti mungapeze zosefera izi m'mafakitale osiyanasiyana.

Ntchito wamba zikuphatikizapo zotsatirazi.

1) Chemical processing

Mutha kupeza zosefera zachitsulo za sintered m'mafakitale osungunulira mankhwala ndi gasi, kuphatikiza

mafakitale a nyukiliya.Kudzimbirika, kutentha kwambiri, komanso kusakhudzidwa ndi mankhwala kumapanga chitsulo chosungunuka

zimasefa mwayi wapadera

makampani opanga mankhwala.

2) Kuyeretsa mafuta

Pakuyenga mafuta, kusefa mafuta osiyanasiyana

Tiyenera kugwiritsa ntchito zosefera zitsulo zosiyanasiyana malinga ndi mlingo wa digiri kuti timalize kusefera kwa

mafuta enieni ochokerachakudya chamafuta.Inde, zosefera zitsulo za sintered zingakuthandizeni kukwaniritsa cholinga ichi.

Chifukwa zosefera zitsulo sizimakhudzidwa ndi mafuta.

Choncho, mafuta enieni adzakhala opanda zodetsa zilizonse mutatha kusefa.

Kuphatikiza apo, mutha kugwiritsa ntchito kutentha mpaka 700 °, zomwe ndizofala pakuyenga mafuta.

3.) Kupanga mphamvu

Kupanga magetsi a hydroelectric kumafuna kugwira ntchito kosalekeza kwa turbine. Komabe, a

chilengedwe muamene turbineimagwira ntchito nthawi zambiri imafunikira kusefera kuti mupeze madzi ambiri

yomwe turbine ilibe zonyansa zilizonse.

Ngati turbine yadzaza ndi zonyansa, imatha kutha ndikulepheretsa turbine kuti isazungulire,

ndiyeno turbine idzateroosapanga magetsi. Mutha kugwiritsa ntchito zosefera zachitsulo za sintered kuti mutsimikizire

mphamvu yopangira mphamvu.

Zoseferazi zimagwiritsidwa ntchito popanga magetsi posefa madzi kuchokera mu turbine.

Chifukwa chosakokoloka ndi madzi, turbine imagwira ntchito kwa nthawi yayitali.

4.) Kupanga gasi wachilengedwe

Mbali ina yofunika yogwiritsira ntchito zosefera zachitsulo za sintered ndi kupanga mpweya.

Zosefera zachitsulo za sintered ndizothandiza kwambiri pakupanga gasi chifukwa samachita ndi mpweya,

ndipo mukhoza kuzigwiritsa ntchitom'malo osiyanasiyana.

5.) Chakudya ndi zakumwa

Zosefera zachitsulo zimachotsa zakudya zofunikira komanso timadziti mumakampani opanga zakudya ndi zakumwa.

Zosefera zachitsulo zimasefa bwino ndikuletsa zakudya izi kuti zisakokoloke pokonza.

Ubwino wa zosefera zachitsulo zomwezo ndikuti samachita ndi zakudya kapena zakumwa zinazake.

Mukamagwiritsa ntchito zosefera izi zimatsimikizira mtundu wa njira yanu yopanga.

9. Ndi mtundu wanjiZosefera za Sintered MetalHENGKO Can Supply ?

HENGKO main supply 316L, 316 and bronze sintered metal filers. mawonekedwe akuluakulu monga mndandanda wotsatira:

1.Fyuluta yachitsulo chosapanga dzimbiriChimbale,

2.Zopanda bangaZosefera ZitsuloChubu,

3.Zopanda banga Zosefera ZitsuloMbale,

4.Fyuluta yachitsulo chosapanga dzimbiriMakapu,

etc., mawonekedwe aliwonse omwe polojekiti yanu ikufuna.

Zedi, timaperekaOEM Service

1.OEMMaonekedwe:Chimbale, Cup,Chubu, Plate ect

2.Sinthani Mwamakonda AnuKukula, Kutalika, Kutali, OD, ID

3.Kukula kwa Pore Mwamakonda /Mabowokuchokera 0.1μm - 120μm

4.Sinthani Mwamakonda Anu Makulidwe osiyanasiyana

5. Mono-wosanjikiza, Mipikisano wosanjikiza, Zosakaniza Zosakaniza

6.Mapangidwe ophatikizika okhala ndi nyumba 304 zosapanga dzimbiri

Kuti mudziwe zambiri za OEM, chonde lemberani HENGKO Today!

Muli Ndi Mafunso Aliwonse Ofuna Kudziwa Zambiri Za Sensor Yowunikira Chinyezi,

Chonde Khalani Omasuka Kuti Mulankhule Nafe Tsopano.

Komanso MukhozaTitumizireni ImeloMwachindunji Monga Motsatira:ka@hengko.com

Tikutumizirani Ndi Maola 24, Zikomo Chifukwa Cha Wodwala Wanu!

Titumizireni uthenga wanu:

Nthawi yotumiza: Aug-20-2022